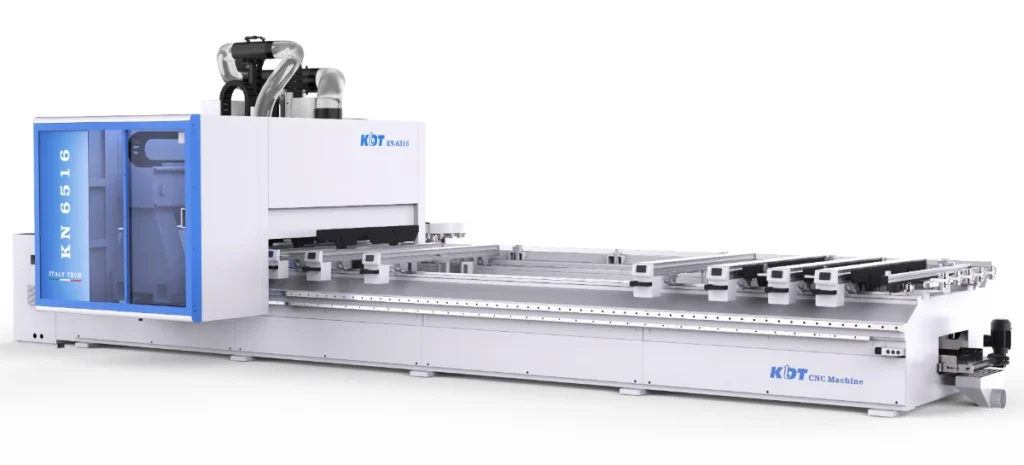

KN-6516C machining centre

Description

KN-6516C MACHINING CENTRE

STRUCTURE

High-strength rigid frame.

Proper heat treatment ensures long-term accuracy.

GANTRY

The Gantry is driven by 2 powerful electronically linked servomotors. The movement is performed by a heavy duty 30 mm rack and pinion system.

Servomotors offer direct-driven linear movements and linear sliders.

They offer accurate positioning at high speed, smooth and vibration-free operation and very easy installation.

HELICAL RACK

Smooth running rack and pinion with low friction. Low noise and long-lasting precision.

The helical rack and pinion system ensures that the rack teeth are fully engaged at all times.

AUTOMATIC LUBRICATION

Automatic lubrication system on the linear guides keeping them in optimum condition at all times and extending their life.

Milling head 13.2kW

Milling unit mounted on the Z-axis.

- Electro motor power: 13.2kW with air cooling.

- Tool locking device: automatic with pneumatic piston.

- Aluminium alloy engine body

- Attack with cones HSK-F63

Motor C-axis

4-axis machining allows a product to be machined from five sides, without additional workpiece rearrangement operations on the worktable, resulting in complex-shaped products with high precision and processing speed.

Tool changes

16-position revolver shift

Automatic linear magazine with 16 positions for main milling units, with HSK-F63 coupling. On/off movement with pneumatic cylinder. Fast automatic tool change with servo, high stability and precision.

Drilling group

Drilling work unit 12V8H1S

Made of light aluminium alloy with high mechanical properties. Pre-selection is automatic by means of pneumatic pistons.

Console table

2 WORKING AREAS

Pendulum mode for non-stop operation. In pendulum mode, idle times for loading and unloading are avoided. The machine will work in one of the working fields, while in the other one the new workpiece to be machined is prepared or the finished work is removed.

8 CONSOLES WITH INDEPENDENT PNEUMATIC LOCKING SCHMALZ K1

Aluminium bar table with suction cups to ensure optimum clamping of workpieces.

The bars move smoothly along the guides and are equipped with pneumatic locking. Smooth operation by means of a side button.

BECKER VACUUM VANE PUMP 160m3/h

A 160 m³/h rotary propeller vacuum pump for vacuum generation.

Dry design and no internal contact makes it the ideal pump for any type of application where dust is a particular concern.

WASTE DISCHARGE CONVEYOR

For collecting shavings and small pieces of wood that become dislodged during machining operations.

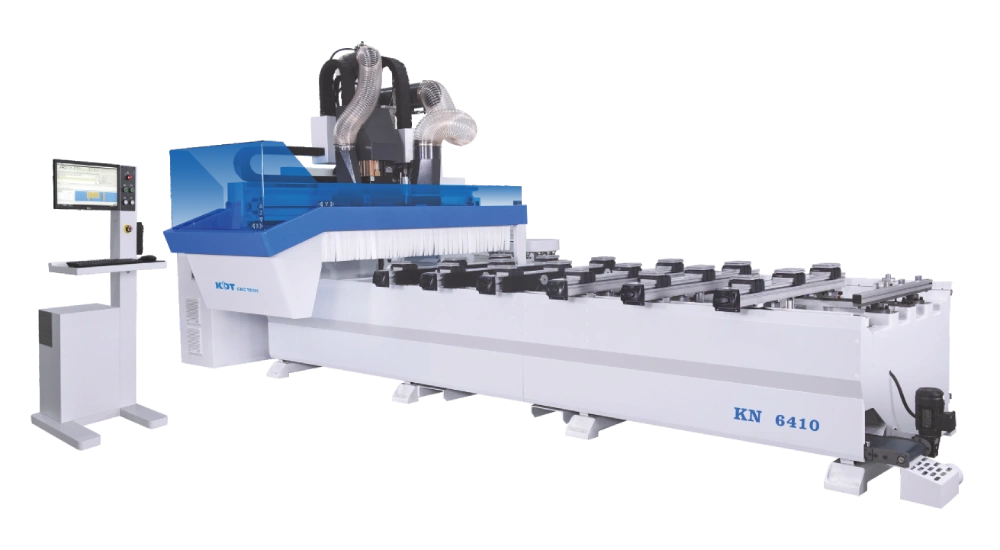

PC INDUSTRIAL COMPUTER SUPPORT MONITOR AND MOBILE CONTROL CONSOLE

Numerical control of the movements of the axes and manoeuvre of the machine. Control PC with CNC design and control software. It manages different parameters such as:

- Tool setting

- Direct reading of files from USB and INTERNAL drives.

- Powerful system for processing and displaying programme files.