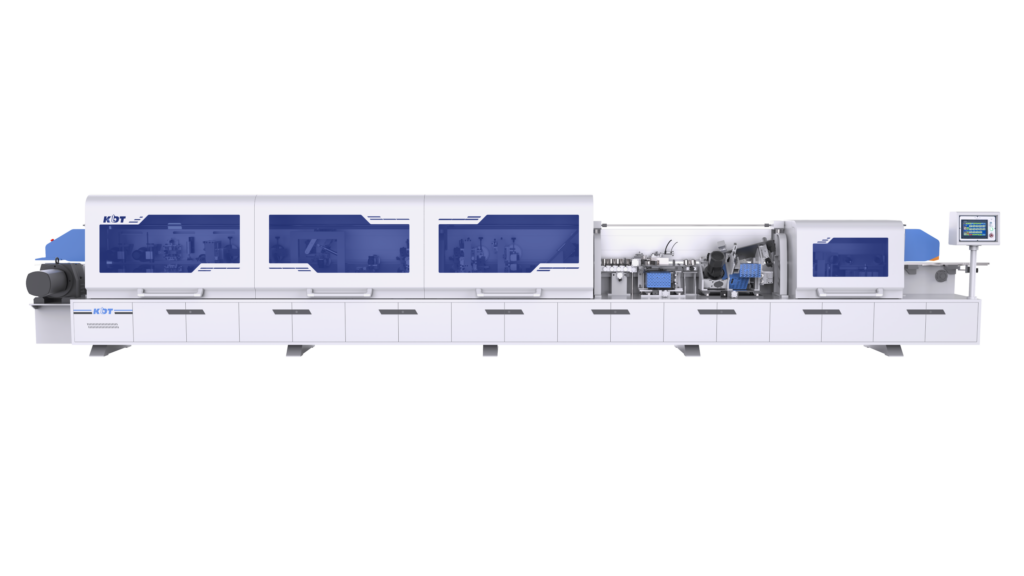

A few weeks ago, the first model of the new gluing machine for angle edging was delivered. The model is the KE-399 and has a very high level of configuration, to be able to carry out the most demanding and precise jobs.

What else can we say about this new model? Several interesting things:

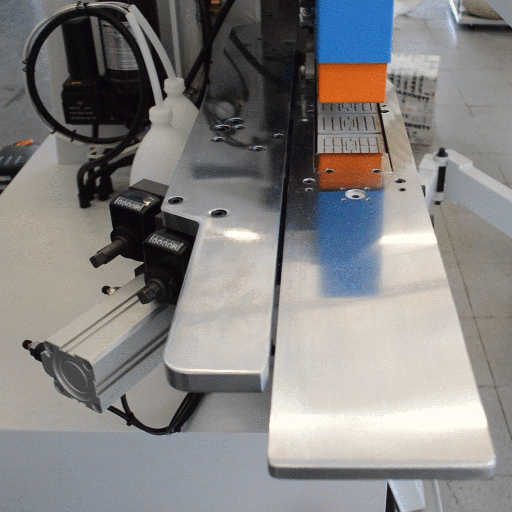

- It has an input guide with automatic positioning from the screen depending on the finish to be worked (straight or inclined).

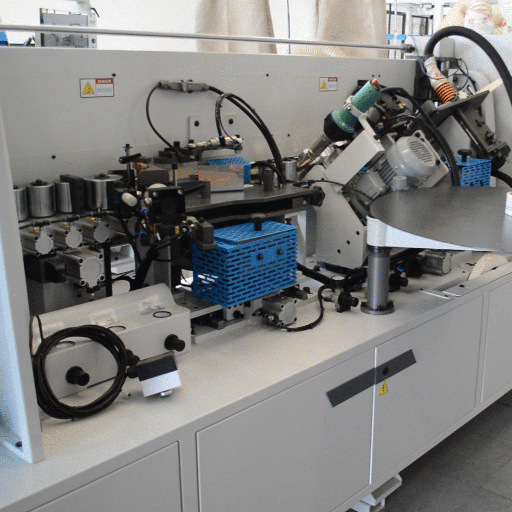

- In order to save more space, the roll holder of the corner gluing unit is integrated into the machine chassis.

- It has double groups of non-stick and cleaning sprays, depending on the finish you are working on, one or the other will be activated.

- Angle gluing unit, end trimming unit and flat glue scraper with pneumatic exclusion. Easily select on the screen which finish you are going to work with and the unit will position itself automatically.

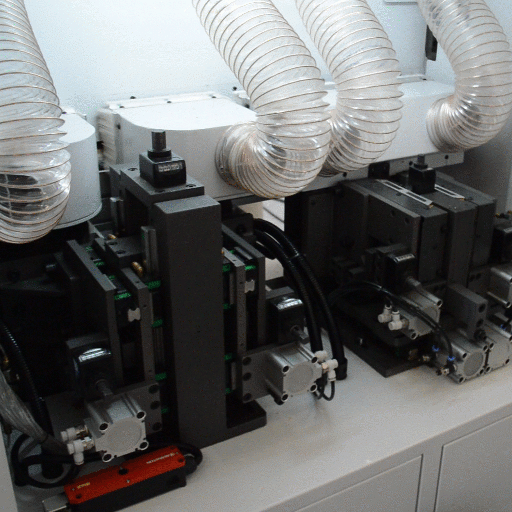

- Edging unit consisting of three units. The first one is a roughing unit, the other two are fine trimming units (one for angled edges and one for straight edges).

- Double scraper group of spokes, one for each type of finish (angular or straight).

And despite all this, which makes it a seemingly complex machine with a very powerful composition and a very strong construction, it is nevertheless a very easy to use gluing machine thanks to its touch screen with intuitive software for quick control and operation of all groups.

Do you want to know more? Write to us and we will send you information without obligation.