Robot + Combinada

Glueing Line in Valladolid - Robot + Combination

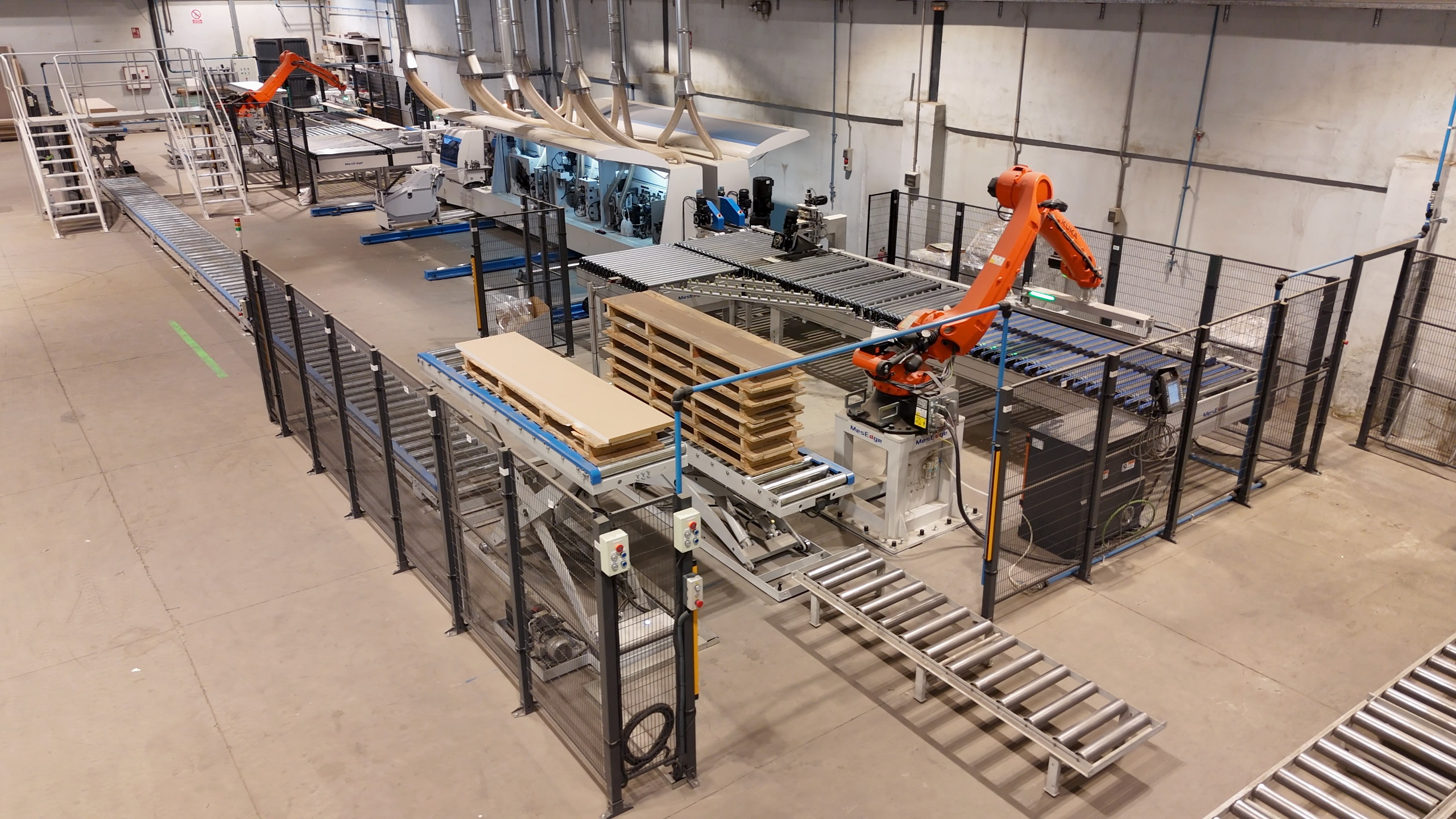

One of the largest furniture manufacturers in the north of Madrid has implemented a double edging line with flexible profilingcombined with a automated robot loading and unloading system for the first and second pass.

The combined machine allows simultaneous grinding and gluing of two of the four sides of the board at high speed. This allows significant time savings in production. At the same time, robot feeding and unloading optimises the entire process, avoiding human error and performing this work efficiently and intelligently.

Depending on whether or not the part has been fully edged, it is either stacked for removal or deposited on the roller line for return to the infeed until the infeed is completed.

Características destacadas:

- Carga y descarga flexible con robot, optimizando el flujo de producción.

- Retorno automático de las piezas, reduciendo la necesidad de intervención manual.

- Sistema inteligente con lista de trabajo integrada, permitiendo una gestión eficiente del proceso.

Con esta modernización, la empresa ha logrado maximizar la producción y garantizar una fabricación ágil y automatizada.