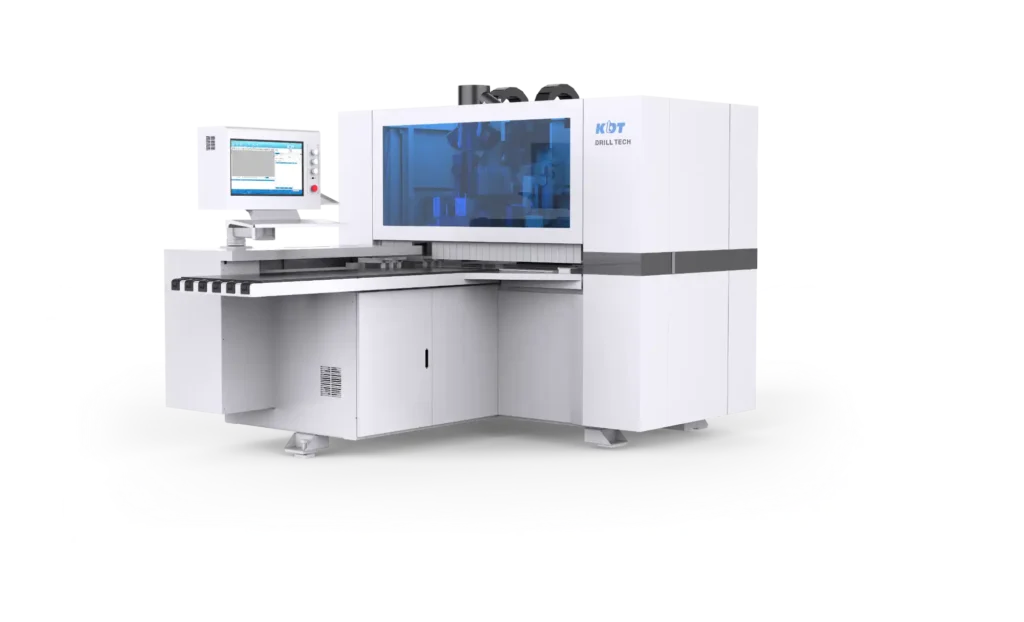

KD-610R CNC Drill

Description

CNC DRILL KD-610R PRECISE 6-SIDED MACHINING IN CONFINED AREAS

Incredibly easy to handle

New CNC drilling for precise machining of all 6 panel faces in the smallest space.

Thanks to its simple but powerful composition, it performs all milling, grooving and drilling work on all sides of the board, while saving space in your workshop.

Loading and unloading from the same position.

WORKPIECE CLAMPS

Double clamp and guide with 2,800 mm travel for fast work up to 25 m/min.

For work with different boards and safety mechanism

GUIDE 2800mm

Compact design to occupy minimum space while maintaining the robustness of its elements.

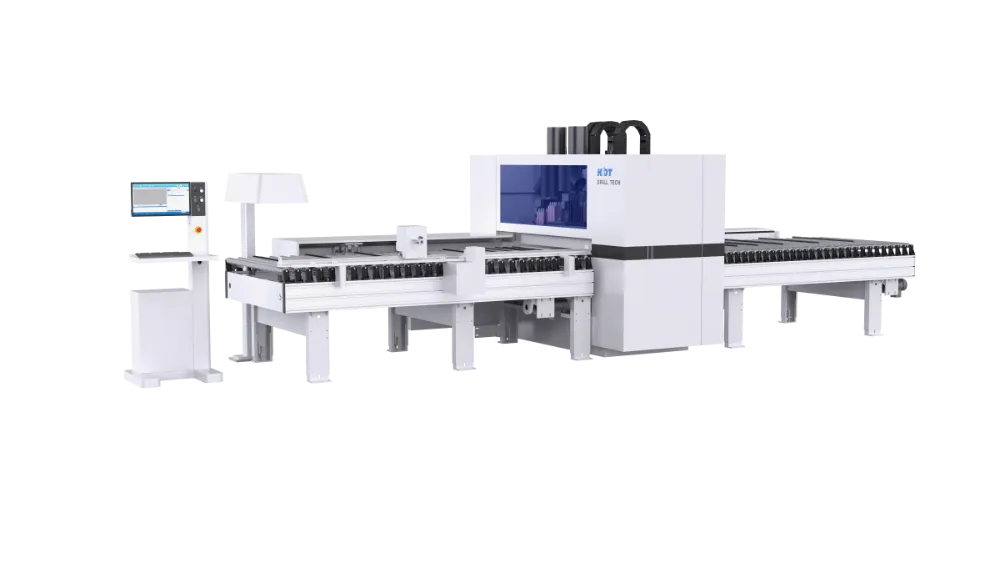

MOBILE AIR CUSHION TABLES

Air cushion tables in two sections that move sideways, moving more flexibly according to the drilling position during the work to avoid scratching or damaging the workpiece or being damaged by the drilling head

PRECISION LATERAL ALIGNER

Lateral alignment mechanism: ensures greater accuracy during the process, as it is held against the panel surface throughout the process.

AUTOMATIC DETECTION OF PANEL MEASUREMENT IN X - Y - Z AXES

The CNC drill is equipped with a full automatic precision part measuring system.

This makes machining easier and avoids possible errors.

The detection of the dimensions of the parts is done in the X - Y - Z axes.

WORKING GROUPS

UPPER AND LOWER DRILLING UNITS

Drilling process of the upper drilling unit together with the milling and sawing unit to increase production efficiency.

The group of holes consists of 10 vertical and 8 horizontal holes in its upper composition and 9 vertical holes in its lower group.

MILLING TECHNOLOGY

3.5kW milling motor with double pressure plate (patented)

It allows a large contact area to be covered, resulting in less vibration during machining and high finishing accuracy.

The air cushion ensures that the workpiece is protected at all times during every movement and is not damaged.

Minimum working dimensions 70x35mm.

DETACHABLE EXTENDABLE TABLES

The extendable entry and exit tables can be assembled and disassembled to save space.

POWER SUPPLY AND OUTPUT SYSTEM

Single-operator system.

Technical Data

THE MANUFACTURER RESERVES THE RIGHT TO MAKE CHANGES WITHOUT PRIOR NOTICE.

The technical data and characteristics mentioned in this offer are of an informative nature and may be subject to modifications, updates and improvements.

Videos

Documentation

Our machines

CNC Drill KD-612KHZ

KD-868A CNC Drill

CNC Drill KD-812ZA

KD-812A CNC Drill

CNC Drill KD-612KHSZA

CNC Drill KD-612KHSZ

CNC Drill KD-612KHSA

CNC Drilling Machine KD-612KHS

CNC Drill KD-612KH

KD-612G CNC Drill

KD-610R CNC Drill

CNC Drill KD-610HZ

KD-610H CNC Drill