Automatic door machining line

Description

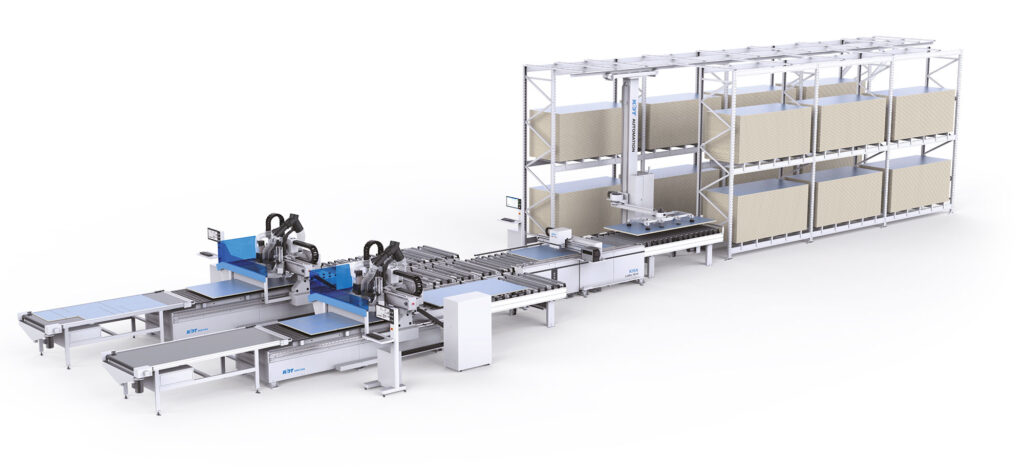

Automatic door machining line

Complete automatic door line to carry out the entire process from the beginning, with the squaring of the door, to the end, which is the complete machining of hinges and locks.

This line is composed of different elements to have a high production estimated at 60 doors/hour.

Elements that make up the line

Gantry feeder and stacker

Gantry system with suction cup bridge for feeding and stacking doors, with three stations: a central one for feeding or unloading the door and two more stations on the sides to leave doors to be fed or to remove the doors already machined.

Feeder and stacker models:

Feeder KHG-250

Stacker KHG-950

Door squaring

KHM-560P

Special CNC designed for precise squaring of door panels and panel parts.

It consists of two longitudinal saws and two transverse saws.

The squaring cuts are made simultaneously on all 4 sides and synchronised to avoid collisions between the units.

Buffer/ Buffer Lung KHS-330

Storage system for boards and finished parts that helps to maintain a constant work flow.

To avoid bottlenecks in the production lines, these lungs or magazines collect the parts that are ejected from each machine and placed vertically.

Return system: feeder and gantry unloader

Bridge feeding or unloading machine. The whole machine is controlled by touch screen + PLC, can be connected (access to central control system), or can be used independently. The whole machine has a heavy duty structure; automatic feeding in 4 directions.

It allows to change the orientation of the pieces so that they can be edged on all four sides.

Double infeed and outfeed tables

The workpieces enter and exit the gluing machine through these tables.

The speed of the rollers is matched to the speed of the gluing machine so that the workpieces are fed in accurately and allow them to be edged correctly.

Single-side gluing machine

Depending on the requirements of speed, edge, groups and dimensions of the workpiece, this line can be equipped with one or another model of edgebander.

Roller tables return system

They form the return system for parts to be glued on all sides.

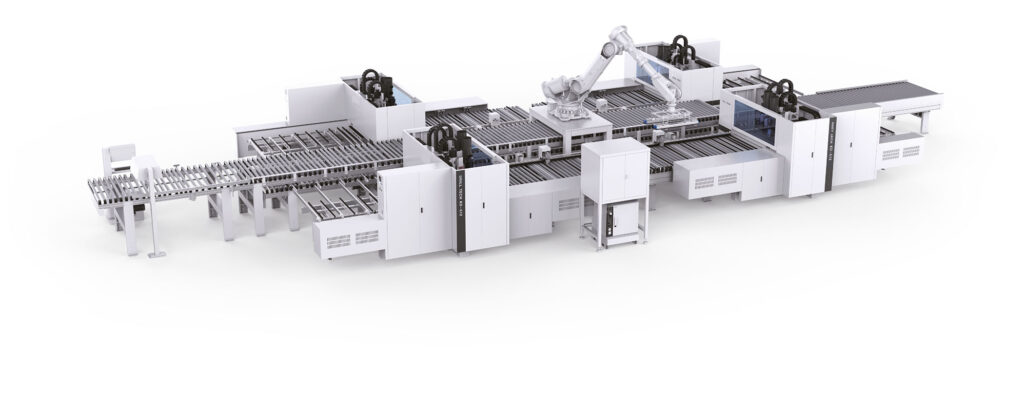

Door machining

KHM-660B

Simultaneous high-speed hinge and lock machining centres.

Automatically adjusts to the size of the door and its working width.

Built with a robust frame for stable machining without vibration.

On this line there are two CNC doors. The infeed tables are positioned at the front and a cross-belt table feeds the second machining centre if it is free.

Another door machining line

Videos

Our machines

Automatic CNC drilling line

Automatic door machining line

Combined automatic double gluing line

Semi-automatic door machining line

Gluing line with automatic return

Automatic double splicer-gluer combination line with loading and unloading

CNC drilling line with automatic feeder, return and stacker

KDT CNC drilling line with return and loading and unloading robot

CNC Nesting line with automatic loading and unloading

KDT CNC drilling line with robot

Nesting line with intelligent storage