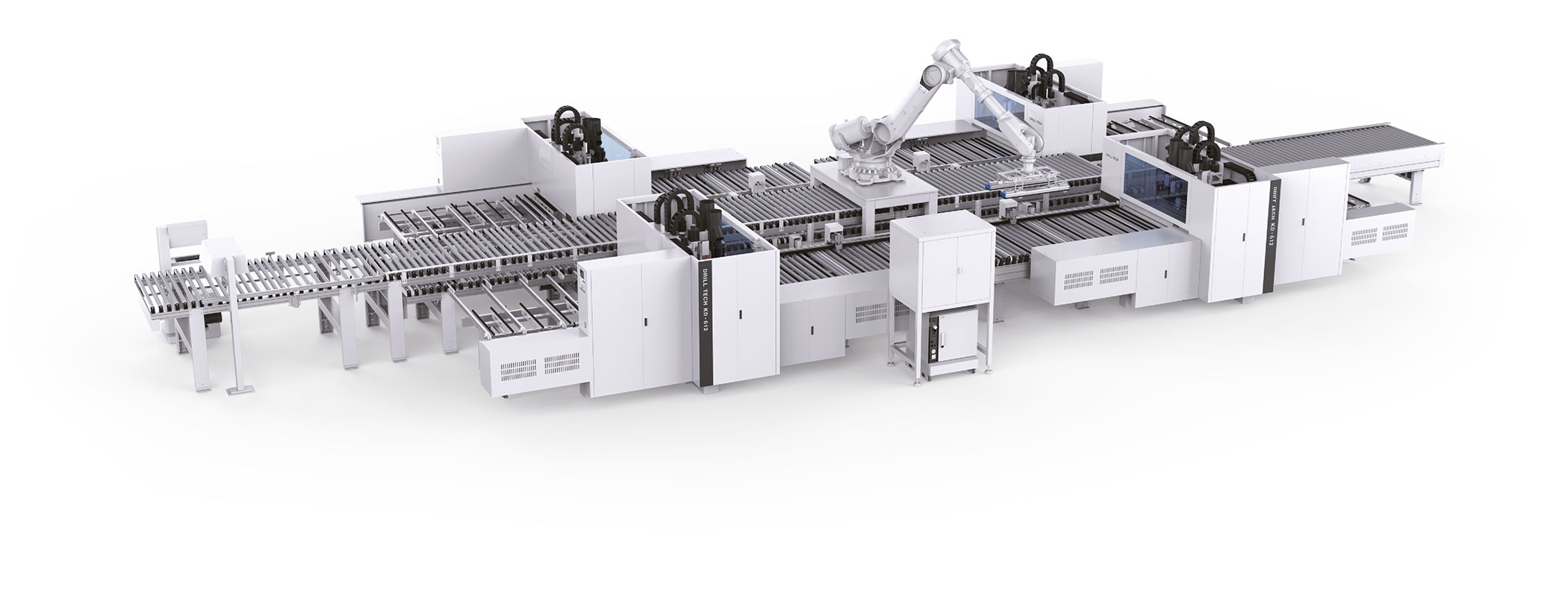

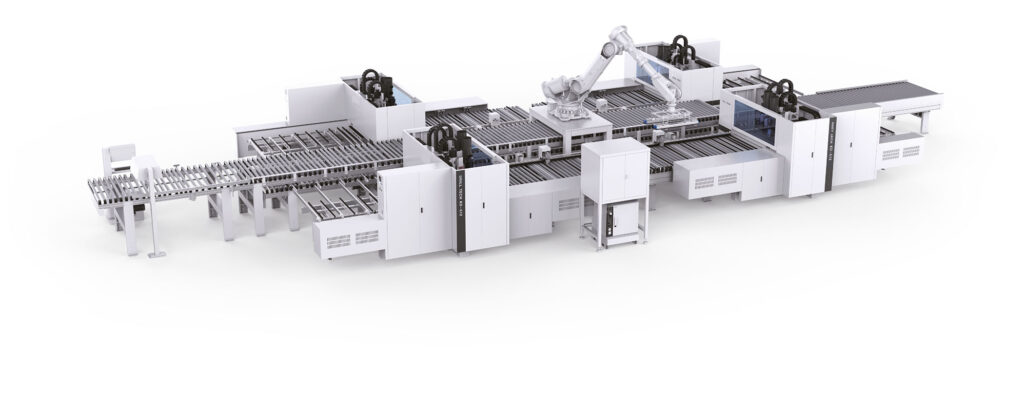

KDT CNC drilling line with robot

Description

Automatic drilling and machining line on all 6 sides of the panel with automatic loading and unloading by robot.

The scanner, located at the infeed, reads the label and sends the information to the line. The central robot is responsible for distributing the parts and delivering them to the appropriate CNC boring machine.

Elements that make up this line

4 CNC drills with automatic feed

Can be supplied with the model equipped with or without tool change.

Model with tool changer: KD-612KHSZA

Model without tool change: KD-612KHSA

Feeding robot

Intelligent automation for parts feeding.

Constant, fast and effortless work. The robot is able to identify the parts and place them where they belong.

A robot can be installed at the entry and exit of the line for fully automatic operation.

This line can be connected to other work cells, such as the gluing cell (upstream of the drilling and machining line) and with the sorting line cell (sorting) at the exit of the machined parts.

Our machines

Automatic double splicer-gluer combination line with loading and unloading

CNC drilling line with automatic feeder, return and stacker

KDT CNC drilling line with return and loading and unloading robot

CNC Nesting line with automatic loading and unloading

KDT CNC drilling line with robot

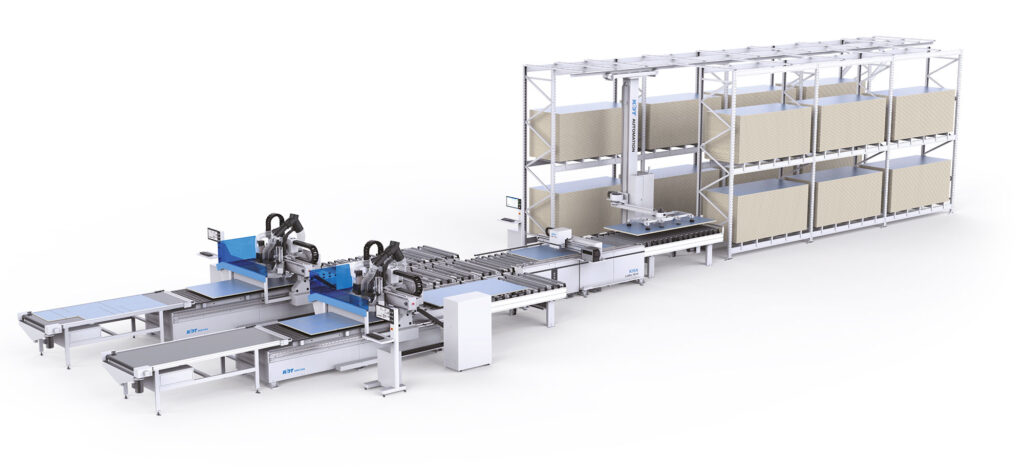

Nesting line with intelligent storage

Automatic CNC drilling line

Automatic door machining line

Combined automatic double gluing line

Semi-automatic door machining line

Gluing line with automatic return