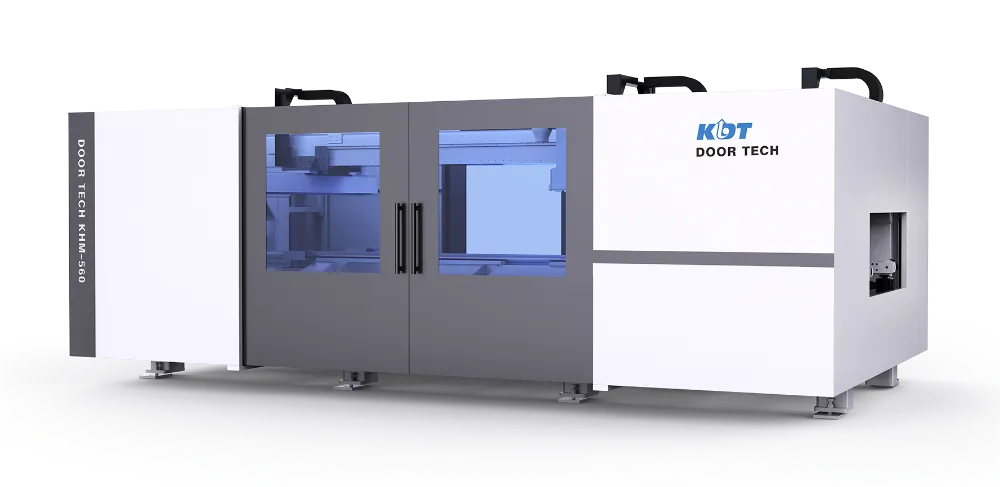

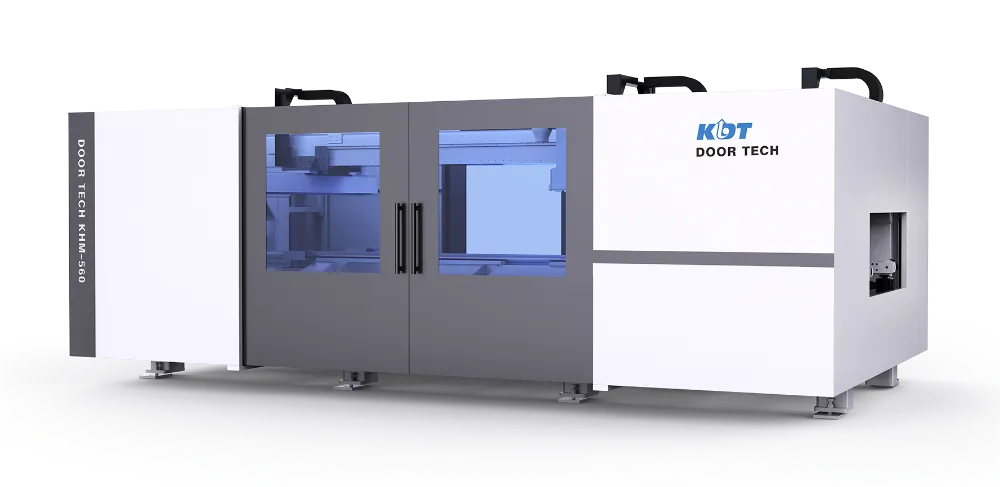

Door squaring KHM-560P

Description

Special CNC designed for precise squaring of door panels and panel parts.

It can operate as a stand-alone solution with a loading and unloading system, or be integrated into an automatic line for door production.

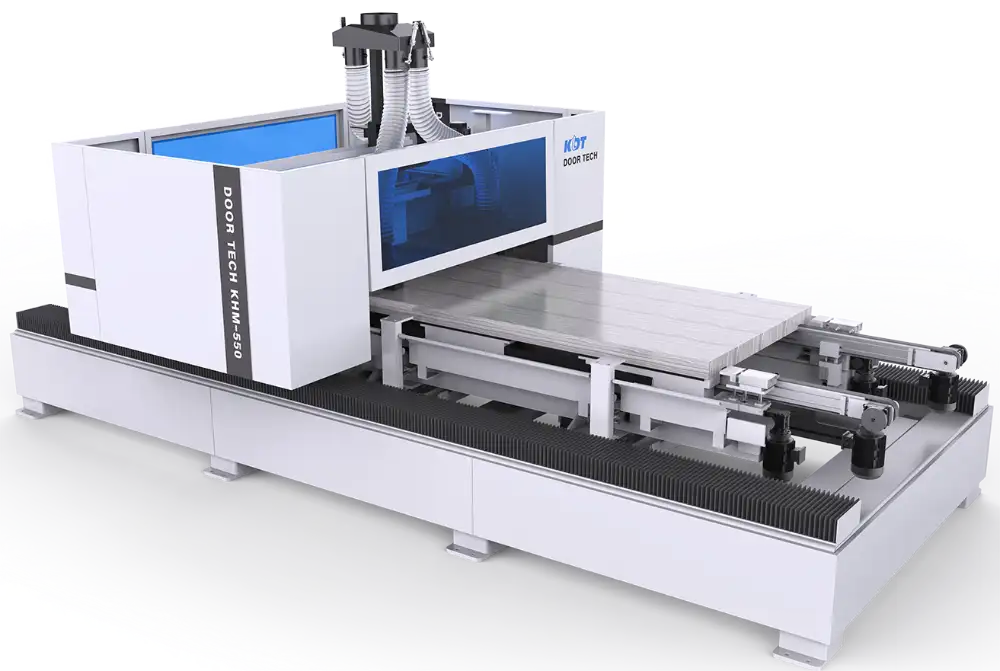

WORKING GROUPS

Two longitudinal saws and two transverse saws.

The squaring cuts are made simultaneously on all 4 sides and synchronised to avoid collisions between the units.

The scoring blades are servo-driven and adjust automatically according to the thickness of the door for a precise cut.

The work table is made up of suction cups that exert a strong vacuum, guaranteeing a firm hold on the door.

POSITIONING OF THE DOOR

The workpiece is positioned and clamped on all four sides of the workpiece by means of powerful pneumatic clamps. The clamps prevent the workpiece from moving during machining.

WASTE DISCHARGE CONVEYORS

Two conveyor belts are positioned on both sides of the working area to efficiently eject the excess cuts from the doors.

CUTTING SOFTWARE

Easy design of door cut-outs.

Operation of all units from the Industrial PC mounted on a mobile lectern for greater ergonomics and operator comfort.

Technical Data

Videos

Documents

Our machines

Door squaring KHM-560P

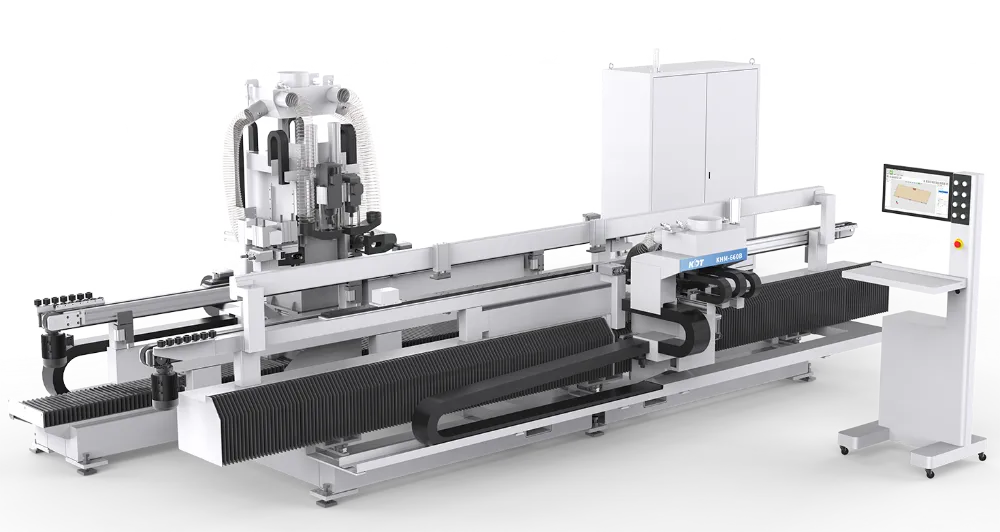

Door machining KHM-660B

Door squaring KHM-550

Door machining KHM-606