Door machining KHM-606

Description

Door machining KHM-606

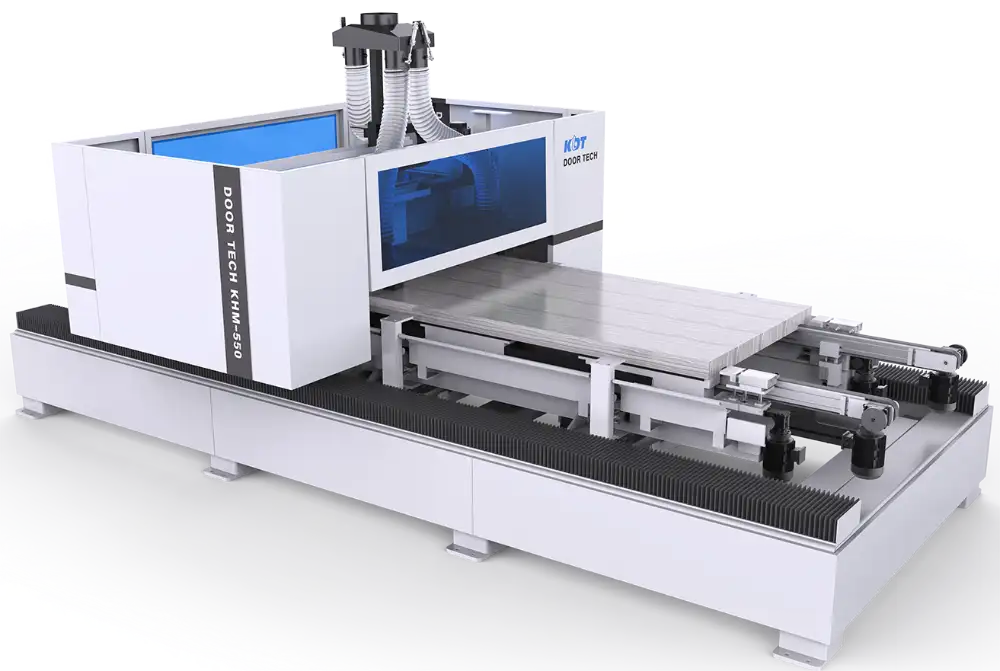

The KHM-606 machining centre is designed for door milling and for the subsequent installation of door hardware: hinges, locks, handles and other door hardware.

The machine allows you to quickly and precisely perform work sequentially on all workpiece planes according to a given programme in semi-automatic mode.

The KHM-606 machining centre is designed for door milling and for the subsequent installation of door hardware: hinges, locks, handles and other door hardware.

The machine allows you to quickly and precisely perform work sequentially on all workpiece planes according to a given programme in semi-automatic mode.

DISTINGUISHING FEATURES

- Solid structure to guarantee precise, vibration-free working.

- Intuitive numerical control.

- Medidor de herramientas

- Palpador vertical para corrección de espesor del cerco

- Barcode scanner, optional.

WORKING GROUPS

The door work is carried out in semi-automatic mode. High-speed milling motors enable high-quality machining. This eliminates the need for additional processing after using the machine. In total, the machine has 2 groups of milling motors working horizontally and vertically.

The dual tool calibration sensor enables accurate measurement of the tools in the vertical and horizontal milling units.

NUMERICAL CONTROL

10-inch high-definition touch screen.

Self-developed software with storage function.

Predefined macros.

With scanner and allows automatic programme retrieval by barcode scanning.

DISPLACEMENT OF THE AXES

Movement of the axes by means of servomotors, integrated in the numerical control for efficient movement in the machining process.

WORK TABLE

It has a large support surface with special material to prevent damage to the workpieces. The workpiece is positioned and clamped on both sides by means of powerful pneumatic clamps.

Technical Data

Videos

Documents

Our machines

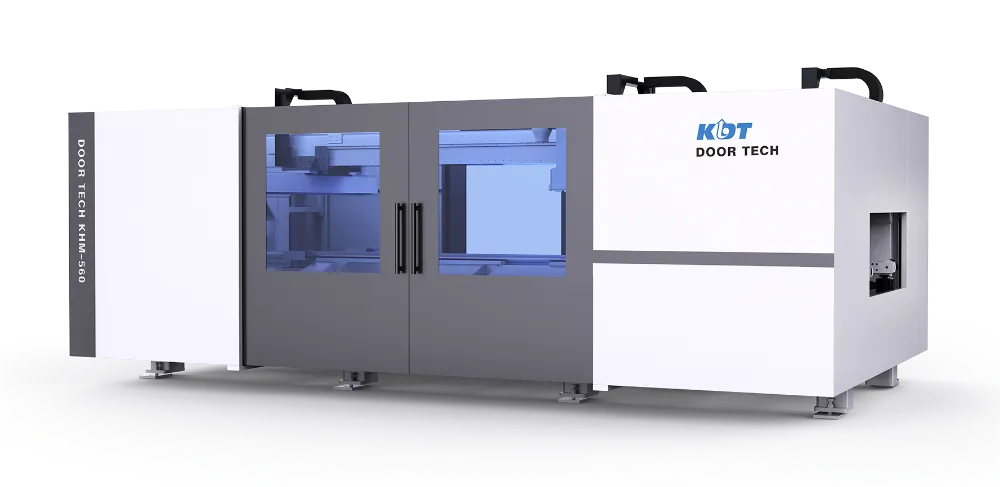

Door squaring KHM-560P

Door machining KHM-660B

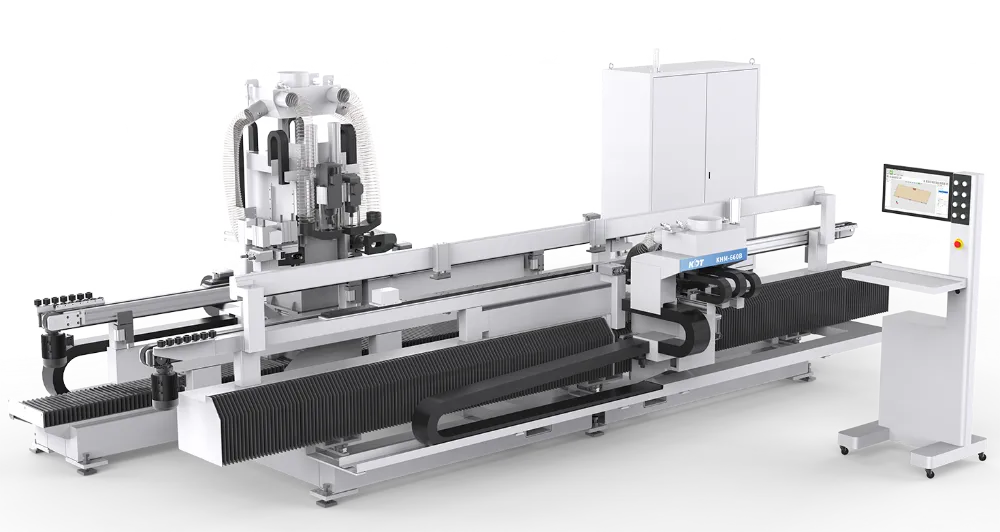

Door squaring KHM-550

Door machining KHM-606