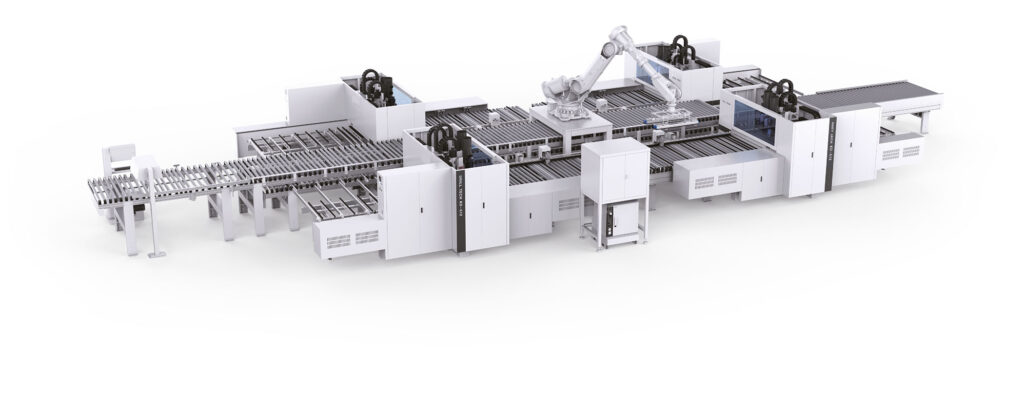

Gluing line with automatic return

Description

This line is made up of two high-speed gluing machines and a return system consisting of roller tables and two double-bridge gantry automatisms which are responsible for orienting the pieces to be glued.

This return system intelligently rotates the workpiece as many times as necessary until the indicated edges have been edged.

Double feeding tables

The workpieces enter the gluing machine through these tables.

The speed of the rollers is matched to the speed of the gluing machine so that the workpieces are fed in accurately and allow them to be edged correctly.

High speed gluing machine

Depending on the requirements of speed, edge, groups and dimensions of the workpiece, this line can be equipped with one or another model of edgebander.

These gluers usually have a larger edgebanding magazine which automatically uses one edge or the other depending on the workpiece. The gluing machines automatically adjust to the thickness of the workpiece and the gluing of each side is also carried out intelligently.

Return system: feeder and gantry unloader

Bridge feeding or unloading machine. The whole machine is controlled by touch screen + PLC, can be connected (access to central control system), or can be used independently. The whole machine has a heavy duty structure; automatic feeding in 4 directions.

It allows to change the orientation of the pieces so that they can be edged on all four sides.

Gluing machines outfeed table

Exit table of the unloading gluing machines. Facilitates the transfer of parts to the next part of the line.

Videos

Our machines

KDT CNC drilling line with return and loading and unloading robot

CNC Nesting line with automatic loading and unloading

KDT CNC drilling line with robot

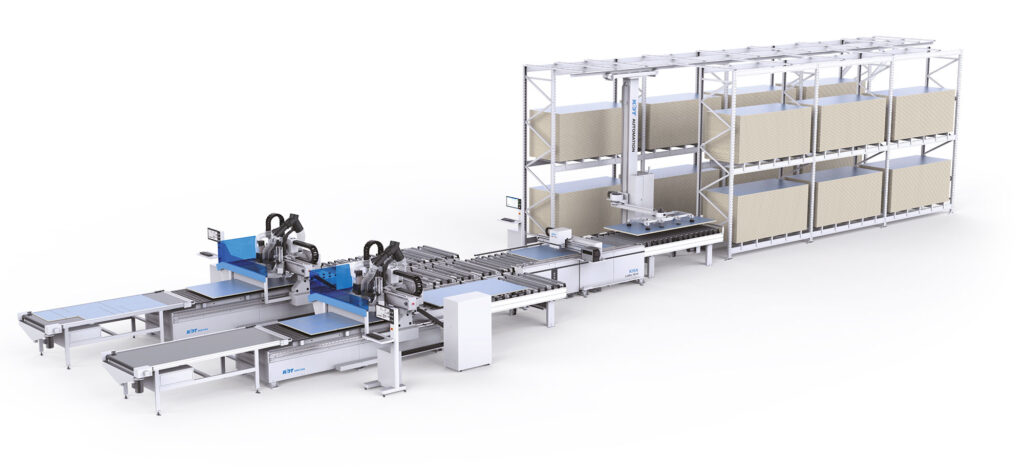

Nesting line with intelligent storage

Automatic CNC drilling line

Automatic door machining line

Combined automatic double gluing line

Semi-automatic door machining line

Gluing line with automatic return

Automatic double splicer-gluer combination line with loading and unloading

CNC drilling line with automatic feeder, return and stacker