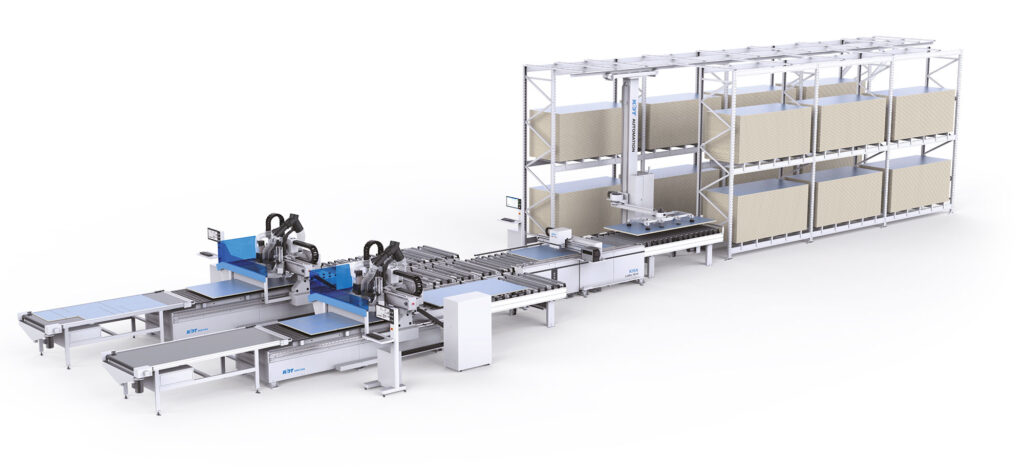

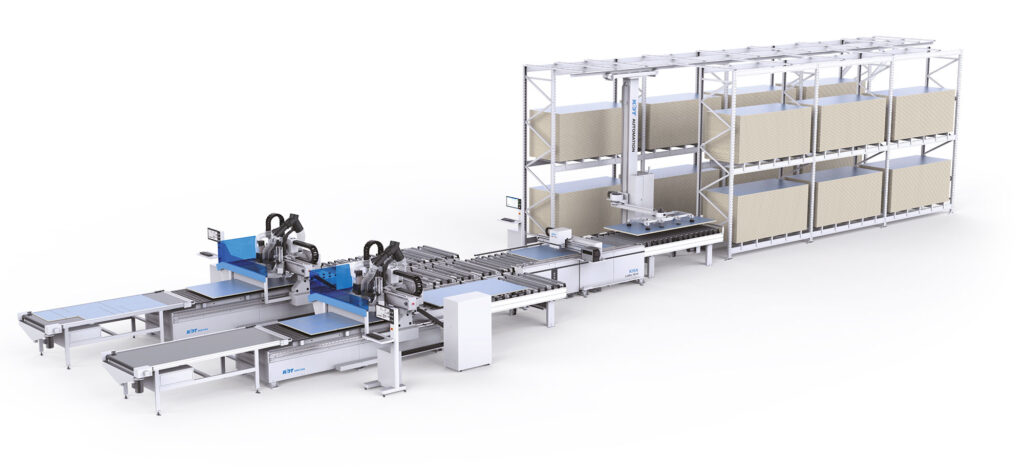

Nesting line with intelligent storage

Description

Nesting line with intelligent storage

Line of 2 CNC Nesting, KDT KN-3 series machining centres with Nesting type vacuum table, equipped with an automatic labeller, feeding and loading tables and unloading tables.

The panels are fed from the intelligent warehouse, which has a vertical stacking space for panels that allows for greater use of space in the factory. The dimensions of the warehouse vary depending on the available space and can be adapted to the customer's needs.

The machining centres carry out the cutting and machining of the panels and, once finished, automatically unload the workpieces thanks to the unloading tables.

Unloading can be done manually or by robot, to continue feeding other intelligent gluing cells.

This results in enormous time savings, a fully automated, fluid workflow and a great optimisation of materials.

Elements that make up the line

Intelligent vertical warehouse

Customisable according to the dimensions of the customer's factory. Thanks to its vertical format we get a great use of space.

A suction arm picks up the boards and places them on the labelling machine or feeding table, so that each of them can be identified before being machined.

The composition of the line will be adapted to the customer's needs, materials, dimensions of the material, etc.

Automatic labelling machine

Located at the beginning of the line, it attaches the labels to the boards in an intelligent way to indicate to which part each piece corresponds.

The labeller is also responsible for squaring the panels. Once it has done its job, it pushes the board onto the roller and cross-belt table located between the machining centres. Models of labelling machine:

Automatic labeller KHA-1713TS

Automatic labeller KHA-1710TS

Feeding table KHC-303S

In this line model there are 3 infeed tables. One right at the exit of the labeller and between the two machining centres. This central table will be in charge of directing the board to one Nesting or the other. Everything will depend on whether one of the CNC's has completed its machining.

The other two tables are part of the panel feed to the machining centre and are positioned one behind each of the panels.

In this way we avoid downtime, because as soon as a machine finishes its work, it receives a new board to be machined. Production is constant and non-stop.

Nesting machining centres

In CNC machining centres, the boards are machined and cut out. Depending on the design assigned to them, they will cut the boards in one way or another. Each CNC works independently of each other and of the previous design. This is a very efficient way to produce a large number of parts of various sizes and shapes.

Some models of CNC nesting tables are:

- Machining centre KN-3710DPC C-axis

- KN-3713D machining centre

- KN-3710D machining centre

Automatic unloading tables

Once the machining centres have finished trimming the boards, they are pushed onto the unloading tables and the mats gradually advance them to the end until they are all removed by the robot.

Some models of unloading tables are:

- Automatic unloading table KHA-9710

- Automatic unloading table KHA-9713

Videos

Our machines

Combined automatic double gluing line

Semi-automatic door machining line

Gluing line with automatic return

Automatic double splicer-gluer combination line with loading and unloading

CNC drilling line with automatic feeder, return and stacker

KDT CNC drilling line with return and loading and unloading robot

CNC Nesting line with automatic loading and unloading

CNC Nesting line with automatic loading and unloading

Nesting line with intelligent storage

Automatic CNC drilling line

Automatic door machining line