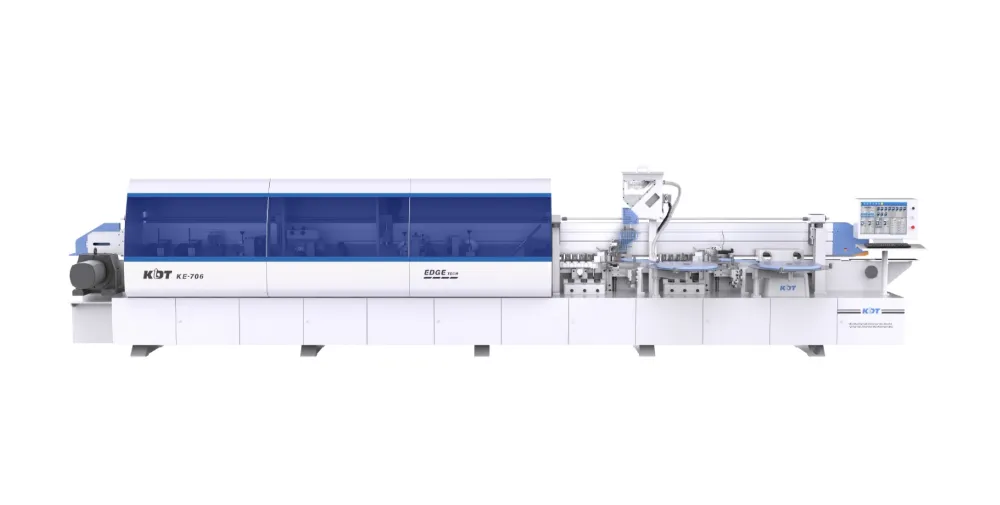

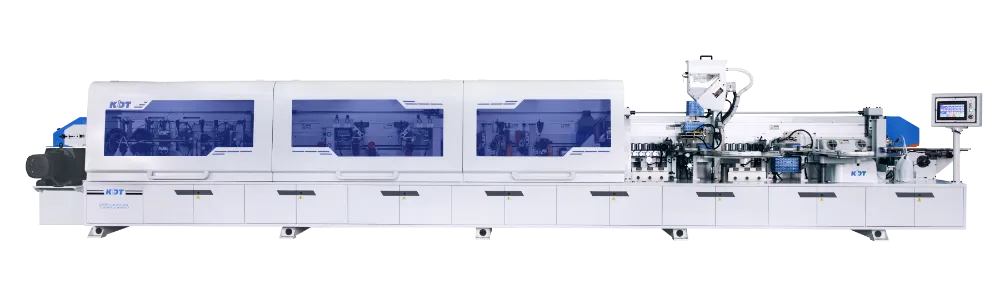

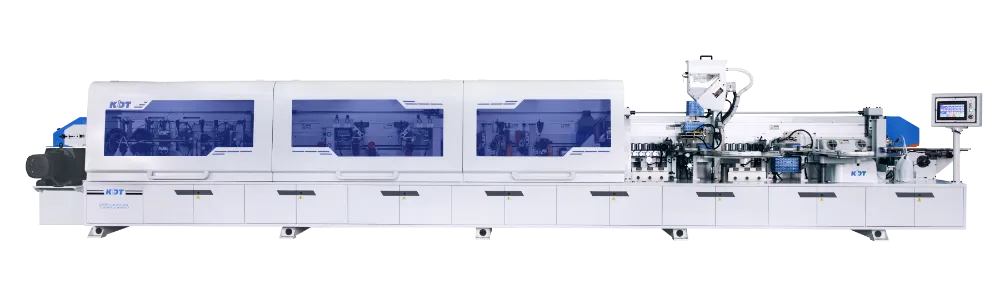

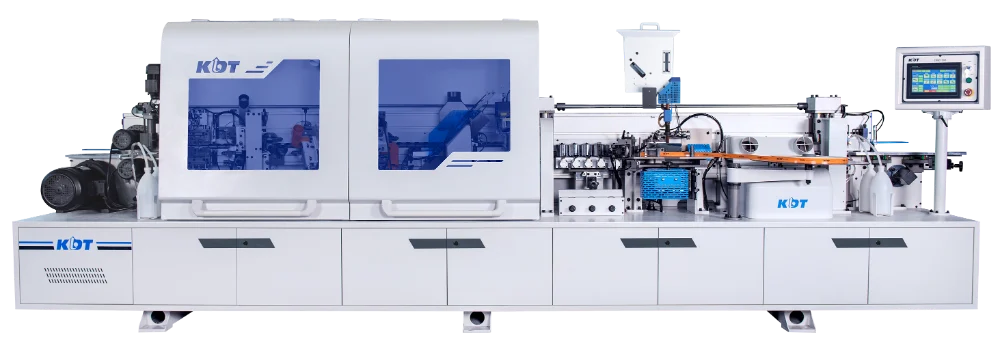

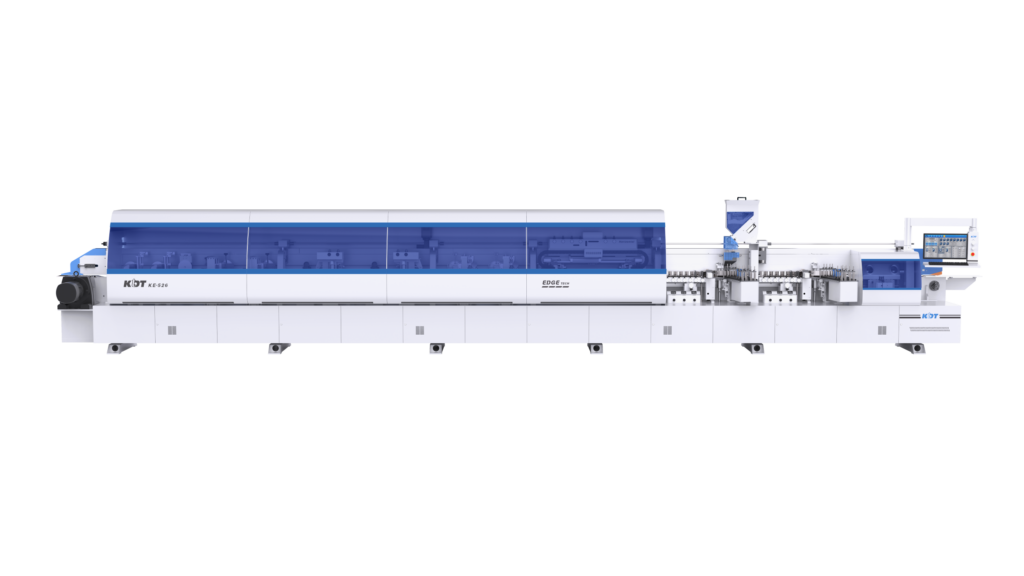

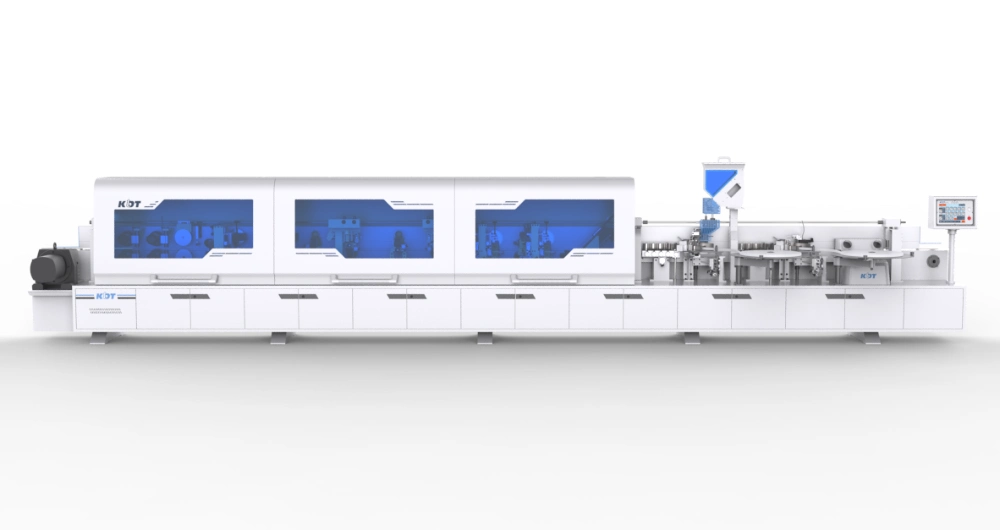

Single-side gluing machine KE-706 CNC

Description

EDGE BANDING MACHINE KE-706 CNC

Uncomplicated control of the essentials for more comfortable and efficient daily work.

CNC CONTROL FOR WORK GROUPS

This is an innovative, very easy and intuitive system designed to facilitate the work of the operator who, at the touch of a button, can change the thickness of the edge, perfectly adjusting the work units, greatly reducing the time spent on the adjustment and achieving excellent finishes from the first piece.

It also has an excellent aid for making the initial settings on the machine whenever a new type of edgebanding is added: the "fine control".

Servo-driven numerically controlled automatic positioning system with servomotors

FINE CONTROL

Operator assistance device for positioning the working units to their exact position. With its high precision, it is able to make a very fine adjustment according to the actual thickness of the edge.

It is a mobile device, which allows the operator to comfortably visualise the operation of the unit to be adjusted during the adjustment itself, thus achieving unequalled finishes.

UPPER PRESSURE BRIDGE

Built on a steel frame, it has a wide rubberised belt mounted on swivel bearings for agile linear movement of the workpiece and optimum clamping.

This group is positioned motorised and is displayed on the machine's screen.

MOTORISED ENTRANCE GUIDE

Large, chrome-plated steel ruler, with double support on prismatic guides and servo-driven numerical control positioning.

Automatic positioning from the PC control.

SWIVEL ROLL HOLDER

With plate for the positioning of PVC - ABS rolls and pre-cut formica strips, with manual loading and automatic feeding.

EDGE LOADER AND SHEARER

For fine edging rolls up to a maximum of 3mm. The machine is supplied with a rubber roller for use in rolls.

INDEPENDENT AND MOBILE EDGE FEEDING SYSTEM

Ensures the length of the excess edge at the front and back of the workpiece. High efficiency and precision in edge feeding.

INDUSTRIAL PC MACHINE CONTROL

Simple operation and diversified functions, customised machining packs. Operators can select the machining programme that best suits their needs at the touch of a button.

On the industrial PC we can store an infinite number of working memories.

NON-STICK SPRAY DEVICE

Spray system installed on the machine with dust-resistant nozzles. Glue residues are prevented from adhering to the workpiece.

TUPI GROUP AT THE ENTRANCE

Positioned before the gluing unit to rectify the edge of the board and eliminate chipping due to a bad cut, obtaining an optimum surface for gluing.

IR LAMP

It allows rapid heating of the panel face, improving the adhesion of the glue, even in unfavourable environmental conditions of temperature and humidity.

GLUE TANK GROUP WITH PREFUSOR

For EVA hot melt glue with fast heating. Digital thermo-regulator for glue tank temperature control.

With the PREFUSER device we achieve maximum glue utilisation under the best conditions.

GLUE TANK

Accessory tank integrated in the chassis which is located under the boiler and is a glue store. A sensor will give the signal to stop the glue filling in the prefuser.

PRESSURE GROUP

Composed of four pneumatic pressure rollers to guarantee a perfect adherence of the applied edge.

Numerical control positioning system.

Self-adjusting mechanism.

Automatic pressure adjustment according to the different requirements of the gluing process.

SUCTION ENDOSUCTION UNIT

Precise rapid unit consisting of two motors for cutting the excess edge of the panel. With automatic positioner from the control panel with the possibility of changing the position of the motors from 0º to 15º.

CNC FINE TRIMMING GROUP

Consisting of 2 independent high frequency motors. Each of the motors has large diameter vertical rotating copiers and horizontal conical copiers for perfect profiling.

Automatic positioning by means of servomotors from the control panel with the possibility of changing the edge thickness measurement.

Automatic change of tool position by servomotor.

ROUNDING UNIT

Pneumatic rounding unit

Allows automatic rounding of the applied edge angles, without the need to stop the workpiece Two-position automatic edge thickness changeover system.

Optimum finishes, with the ability to adapt to different board profiles without special adjustments or programming of the device.

RADIO WIPER UNIT

For a perfect finish on PVC-ABS edges up to 3 mm, eliminating all edge corrugations.

Automatic positioning from the control panel by servomotor.

Exclusion from the group from the table

Automatic tool change

One-button changeover on the machine, intelligent and efficient operation.

Automatic changeover between R1- R2 scraper and adjustment by servomotor.

FLAT TAIL SCRAPER UNIT

Upper and lower tail scraper group.

Equipped with feeler discs.

CLEANING SPRAY

Cleaning liquid. By applying the cleaner before the cloth polishing discs, loose glue residues are removed.

PULECANTOS GROUP

Composed of 2 independent motors of 0,18kW working at 1400 RPM for easy cleaning and shining of the edge.

Technical Data

THE MANUFACTURER RESERVES THE RIGHT TO MAKE CHANGES WITHOUT PRIOR NOTICE.

The technical data and characteristics mentioned in this offer are of an informative nature and may be subject to modifications, updates and improvements.

Videos

Documents

Our machines

Single-side gluing machine KE-706GBSU Laser

Single-side gluing machine KE-706GB

Single-side gluing machine KE-706 CNC

Single-side gluing machine KE-668JSGAU (45)

Single-side gluing machine KE-668JGB

One-side gluing machine KE-665JSKA

Single-side gluing machine KE-665JHSKA

One-side gluing machine KE-655JSKA

Single-side gluing machine KE-526G

Single-side gluing machine KE-520GU

Single-side gluing machine KE-496GH

Single-side gluing machine KE-493G (40)

Single-side gluing machine KE-493 (40)

Single-side gluer KE-468JSKGA (45)

Single-side gluer KE-468JSKGA