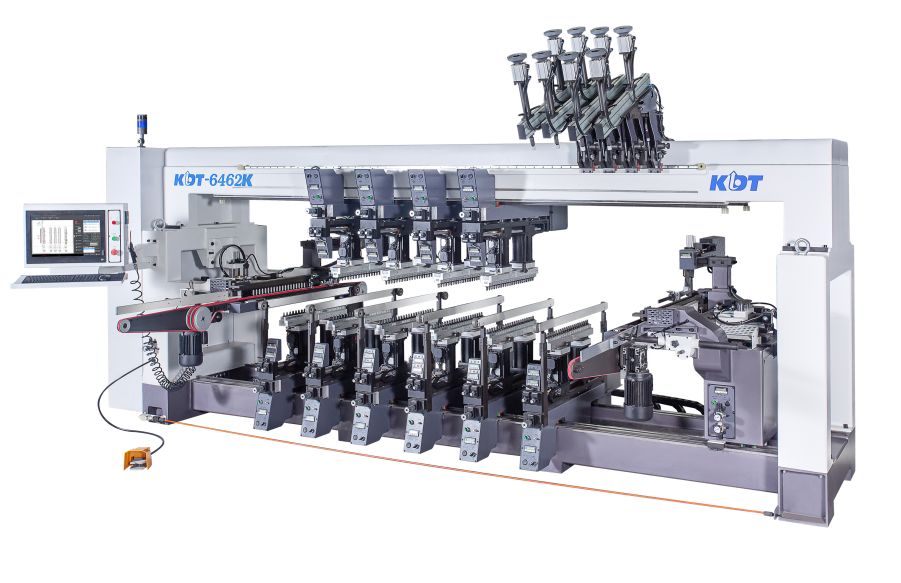

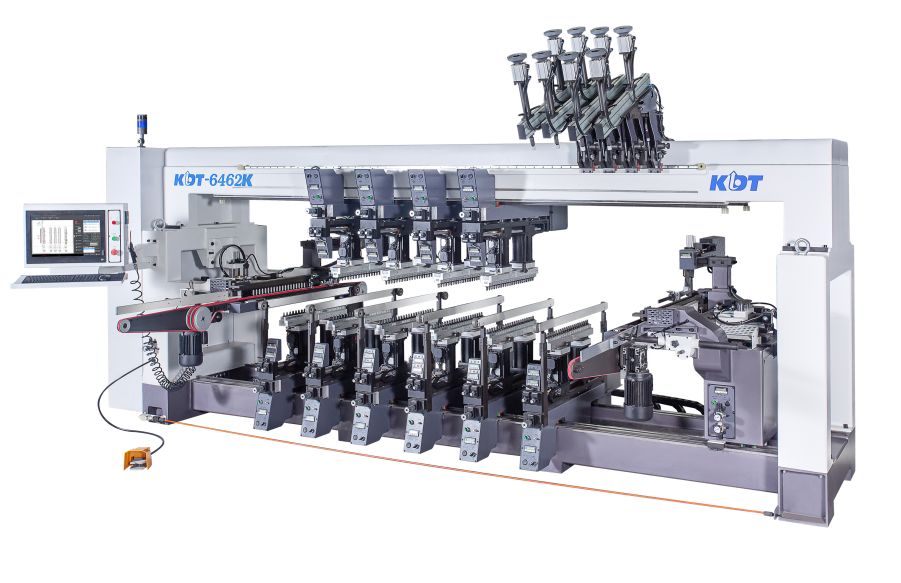

Multi-drill KN-6462K

Description

MULTI-PURPOSE DRILL KN-6462K

Automatic multi-drill for the drilling up to 4 panel faces sequentially or simultaneously.

It has automatic infeed and outfeed with precise positioning and firm clamping of the workpieces with very fast movements in order to be able to perform up to 22 cycles per minute.

Robust construction, with an over-dimensioned structure and work elements that allow it to work up to 3 shifts continuously.

Powerful cross-drilling motors ensure fast and precise insertion of the required holes in the workpieces.

Composition of the machine:

- 2 units of fixed horizontal drills of 21 bits each

- 6 units of lower vertical drills of 11+11 bits each (90° rotatable split combs)

- 4 units of upper vertical drills 11+11 drills each (90° rotating split combs)

The workpiece is drilled from all four sides, which guarantees the processing of most workpieces in a single work cycle.

The automatic positioning of the stops along the width of the workpiece according to the workpiece. This guarantees high precision and minimum time to reconfigure the machine from one workpiece to another.

The pneumatic cylinders have the ability to move to match the size of the workpiece, thus fixing it securely and precisely in the work area.

Upper suction cups to hold panels.

Automatic feeding of the workpieces into the working area ensures maximum productivity of the machine in series production. The machine can work in two modes:

- In line: two operators.

- One way and return: one operator

Quick Cycle Technology

Automatic positioning of the working units

The machine is equipped with digital counters, which makes it possible to quickly change from one size to another. Pneumatic brakes firmly fix the drilling crossbeams and ensure stability and precision.

Fast positioning of the drilling units with digital LCD liquid crystal display for reading the positioning.

Touch screen for selection of working units, choice of working cycle, setting of working cycle parameters, etc.

PC control with automatic drilling software with remote control available. With integrated editor.

Technical Data

THE MANUFACTURER RESERVES THE RIGHT TO MAKE CHANGES WITHOUT PRIOR NOTICE.

The technical data and characteristics mentioned in this offer are of an informative nature and may be subject to modifications, updates and improvements.

Our machines

Multi-drill KN-6462K

Multi-drill KN-6062K

Multi-drill KN-6042TSL

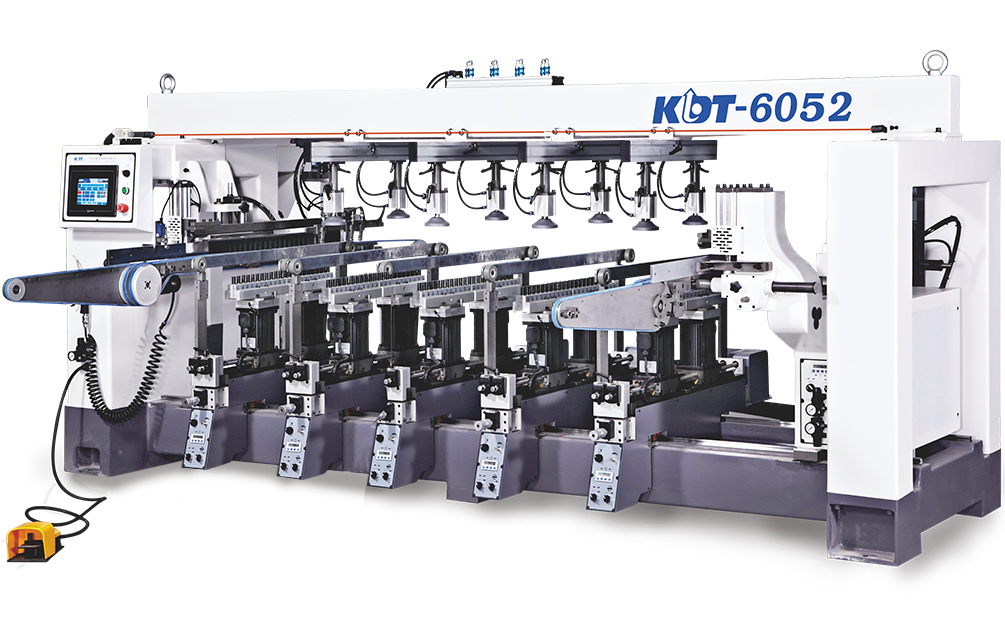

Multi-drill KDT-6052

Multi-drill KDT-533