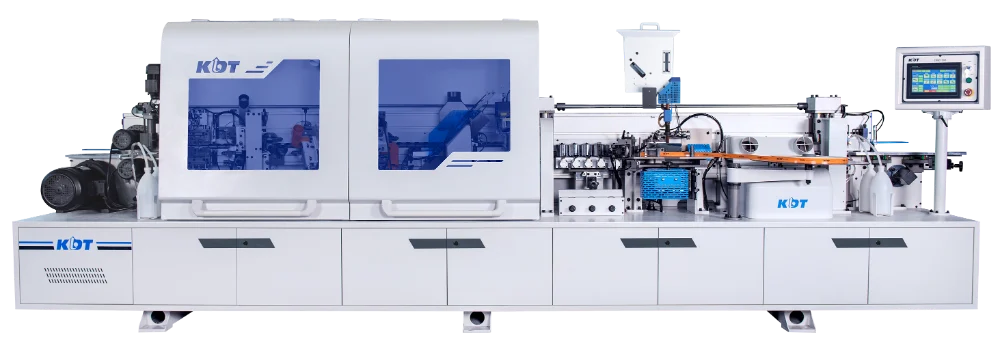

Single-side gluer KE-468JSKGA

Description

EDGE BANDING MACHINE KE-468JSKGA DOUBLE BOILER

New range of machinery consisting of single-side straight edge banding machines with suspended dashboard and 10-inch touchscreen display equipped with gluing, trimming and profiling units in its basic machine series. It also incorporates a scraper unit for a perfect finish, with 2 mm radius blades, double edge polishing unit and rounding unit ideal for kitchen furniture.

UPPER PRESSURE BRIDGE

Constructed with a steel frame with double rows of rubber wheels mounted on bearings for agile linear movement of the workpiece and optimum clamping.

DOUBLE ROLL HOLDER

With 650 mm diameter plate for the positioning of PVC - ABS rolls and pre-cut formica strips and strips with manual loading and automatic feeding.

EDGE LOADER AND SHEARER

For fine edging rolls up to a maximum of 3mm. The machine is supplied with a rubber roller for use in rolls.

SUSPENDED CONTROL PANEL (TOUCHSCREEN)

From the touch screen, the main functions of the machine are controlled and all the operating units are started. Easy, fast and intuitive, thanks to its direct connection to the PLC.

NON-STICK SPRAY DEVICE

Spray system installed on the machine with dust-resistant nozzles. Glue residues are prevented from adhering to the workpiece.

TUPI GROUP AT THE ENTRANCE

Positioned before the gluing unit to rectify the edge of the board and eliminate chipping due to a bad cut, obtaining an optimum surface for gluing.

DOUBLE IR LAMP

It allows rapid heating of the panel face, improving the adhesion of the glue, even in unfavourable environmental conditions of temperature and humidity.

DOUBLE GLUE TANK UNIT WITH PREFUSOR

For EVA hot melt glue with fast heat-up time of approx. 12 minutes. Digital thermo-regulator for glue tank temperature control. Automatic reduction of the temperature of the unit.

With the PREFUSER device we achieve the maximum use of the adhesive and keep the glue tank in the best conditions for a longer period of time.

DOUBLE PRESSURE ROLLER UNIT

Each group is composed of four rollers with continuous pneumatic pressure to favour the adherence of the edge to the workpiece.

SUCTION ENDOSUCTION UNIT

Precise rapid unit consisting of two motors for cutting the excess edge of the panel. With automatic positioner from the control panel with the possibility of changing the position of the motors from 0º to 15º.

DOUBLE EDGING UNIT

Consisting of a first roughing unit and a second fine trimming unit.

Both groups with automatic positioner from the control panel with the possibility of changing two edge sizes.

ROUNDING UNIT - MAXIMUM SPEED 18m/min

It allows the automatic rounding of the angles of the applied edge, without the need to stop the piece. This rounding device has the following main characteristics:

- Optimum finishes, with the ability to adapt to different board profiles without special adjustments or device programming

SCRAPER GROUP OF SHAPES

For perfect finishing of PVC-ABS edges up to 3mm, eliminating all edge undulations. Automatic positioner from the control panel with the possibility to change two edge sizes.

FLAT TAIL SCRAPER UNIT

Upper and lower tail scraper group.

Equipped with large diameter feeler discs.

Easy to clean swarf collection box inserted in the suction system.

CLEANING SPRAYS

Cleaning liquid. By applying the cleaner before the cloth polishing discs, loose glue residues are removed.

DOUBLE PULECANTOS GROUP

Composed of 2 independent motors of 0,18kW working at 1400 RPM for easy cleaning and shining of the edge.

Optional - Extras

The items listed below are not included in the standard machine described unless otherwise stated.

LOWER GROOVING UNIT

Pneumatic, automatic, vertical grooving and depth adjustable spindle moulder unit.

Possibility to work in linear and automatic continuous operation with time-controlled exclusion from the screen.

3.7 kW power.

NESTING PROBES

Set of styli essential for machining workpieces that have been previously machined using the nesting system on the upper side.

Technical Data

THE MANUFACTURER RESERVES THE RIGHT TO MAKE CHANGES WITHOUT PRIOR NOTICE.

The technical data and characteristics mentioned in this offer are of an informative nature and may be subject to modifications, updates and improvements.

Videos

Documents

Our machines

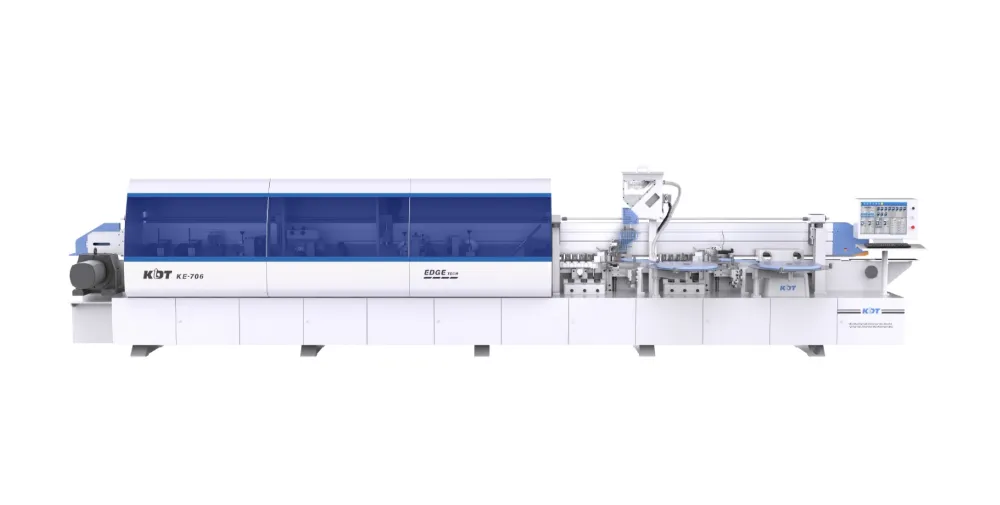

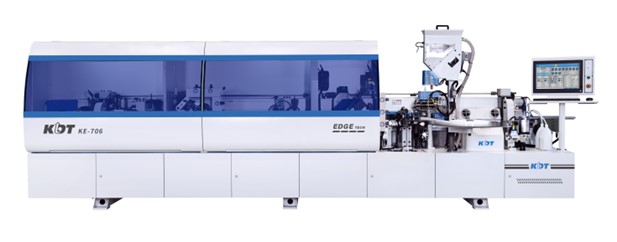

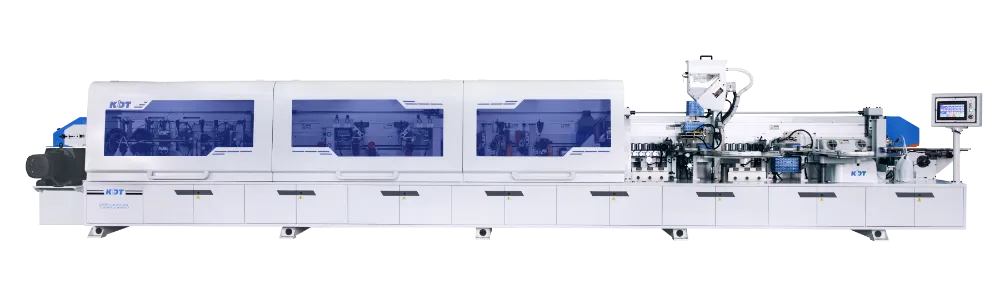

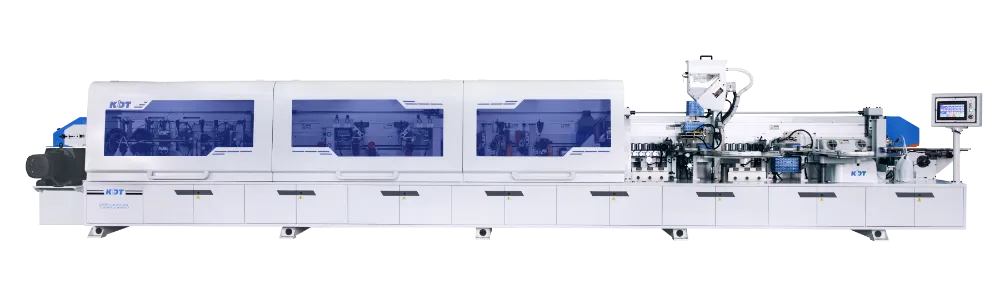

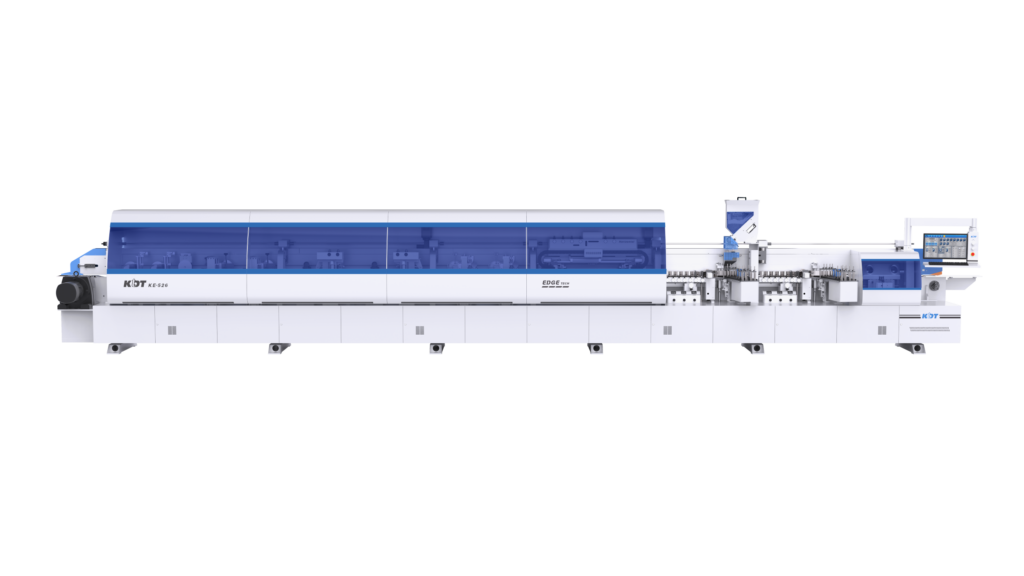

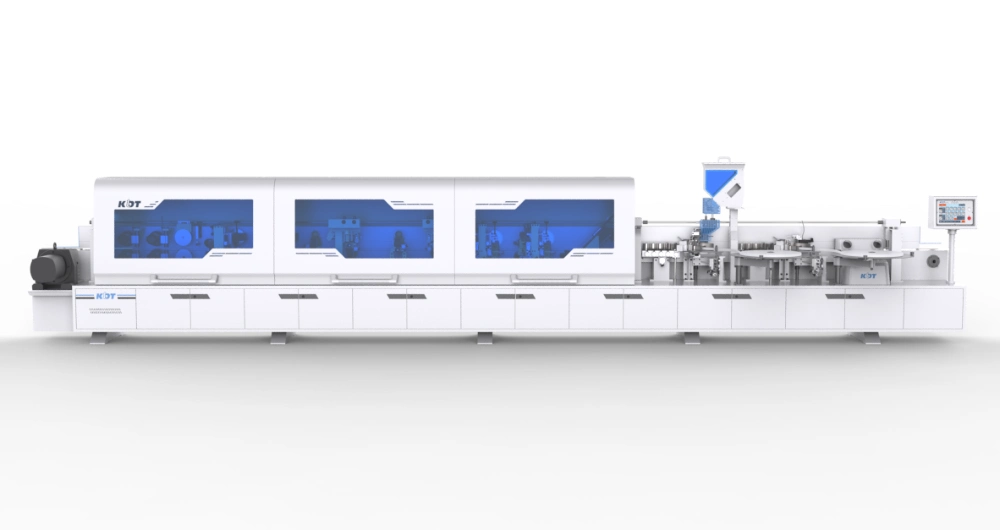

Single-side gluing machine KE-706GBSU Laser

Single-side gluing machine KE-706GB

Single-side gluing machine KE-706 CNC

Single-side gluing machine KE-668JSGAU (45)

Single-side gluing machine KE-668JGB

One-side gluing machine KE-665JSKA

Single-side gluing machine KE-665JHSKA

One-side gluing machine KE-655JSKA

Single-side gluing machine KE-526G

Single-side gluing machine KE-520GU

Single-side gluing machine KE-496GH

Single-side gluing machine KE-493G (40)

Single-side gluing machine KE-493 (40)

Single-side gluer KE-468JSKGA (45)

Single-side gluer KE-468JSKGA