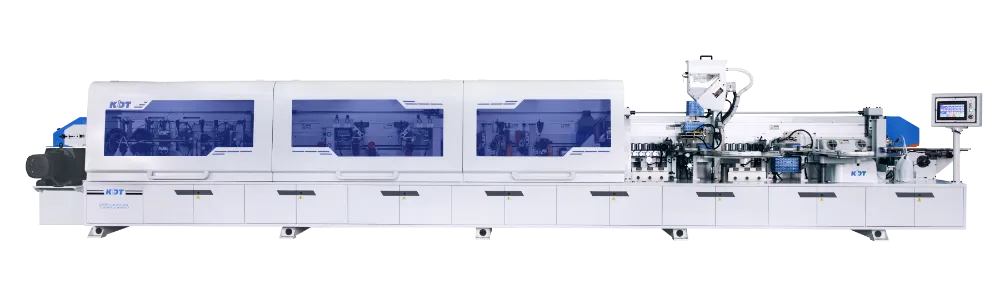

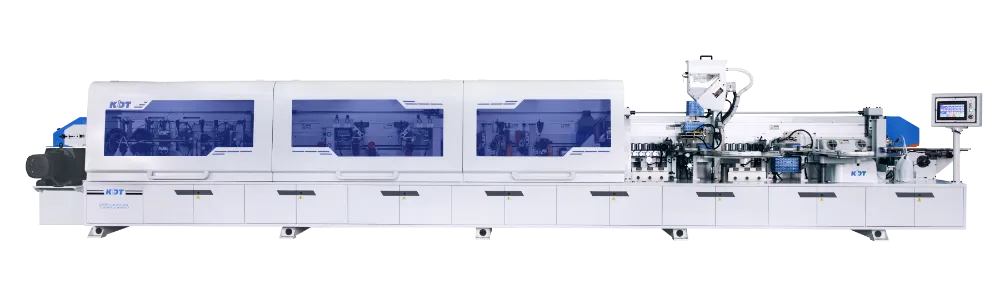

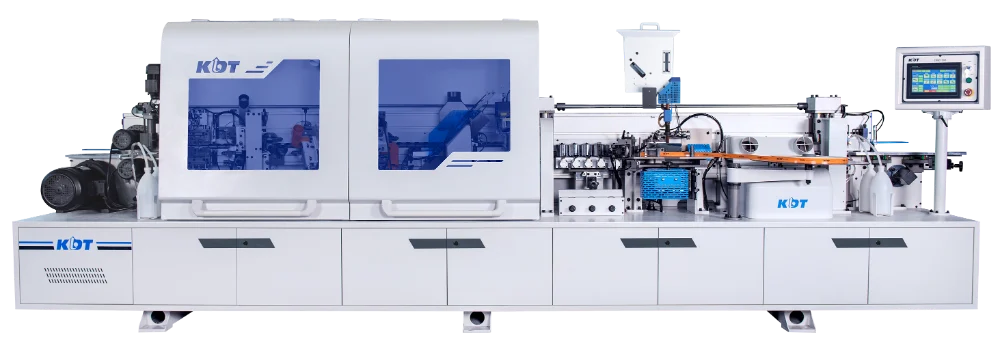

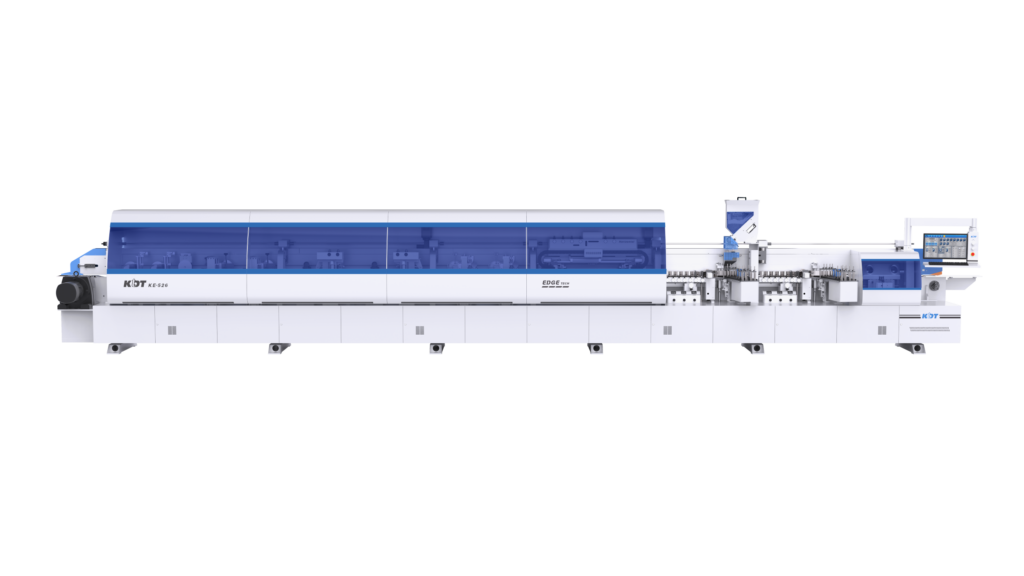

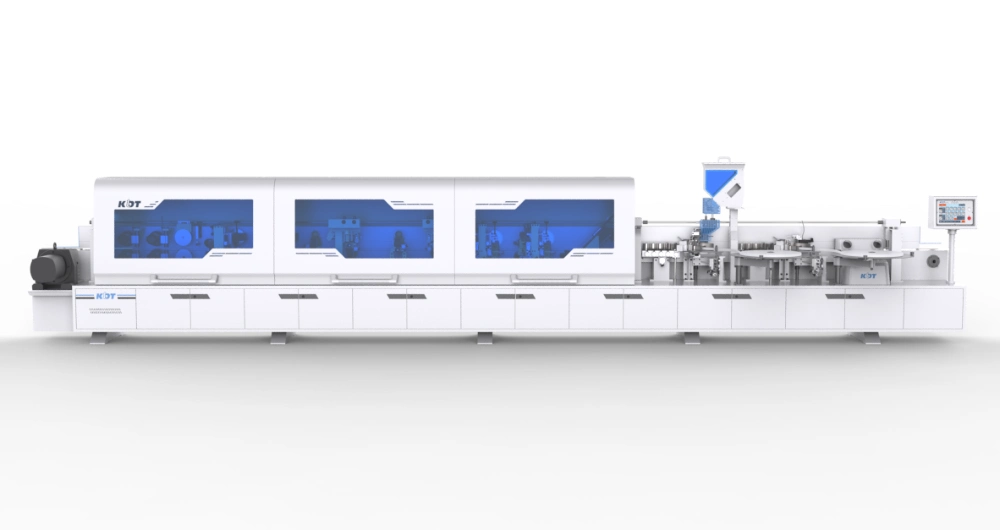

Single-side gluing machine KE-520GU

Description

HIGH SPEED GLUING MACHINE KE-520G DOUBLE BOILER

UPPER PRESSURE BRIDGE

Made of steel, its strong support guarantees the best clamping of the workpiece.

Automatic positioning of the pressure bridge

Fast and accurate adjustment according to the thickness of the workpiece, reducing time and improving process efficiency.

MOTORISED ENTRANCE GUIDE

With double support on linear guides and Numerical Control. Automatic positioning from PC control.

DOUBLE TROLLEY

Two mobile trolleys for the positioning of 2 rolls of PVC - ABS with manual feed.

EDGE LOADER AND SHEARER

For fine edging rolls up to a maximum of 3mm. The machine is supplied with a rubber roller for use in rolls.

Shear for cutting PVC and ABS up to 3 mm thick.

INDUSTRIAL PC MACHINE CONTROL

Simple operation and diversified functions, customised machining packs. Operators can select the machining programme that best suits their needs at the touch of a button.

On the industrial PC we can store an infinite number of working memories.

NON-STICK SPRAY DEVICE

Spray system installed on the machine with dust-resistant nozzles. Glue residues are prevented from adhering to the workpiece.

TUPI GROUP AT THE ENTRANCE

Positioned before the gluing unit to rectify the edge of the board and eliminate chipping due to a bad cut, obtaining an optimum surface for gluing.

DOUBLE IR LAMP

It allows rapid heating of the panel face, improving the adhesion of the glue, even in unfavourable environmental conditions of temperature and humidity.

DOUBLE GLUE TANK UNIT WITH PREFUSOR

For EVA hot melt glue with fast heat-up time of approx. 12 minutes. Digital thermo-regulator for glue tank temperature control. Automatic reduction of the temperature of the unit.

With the PREFUSER device we achieve the maximum use of the adhesive and keep the glue tank in the best conditions for a longer period of time.

DOUBLE PRESSURE ROLLER UNIT

Each group is made up of five rollers with continuous pneumatic pressure to promote the adherence of the edge to the workpiece.

HORIZONTAL HIGH-SPEED CROSS-CUT SAW UNIT

The horizontal cross-cutter cuts at the front and back edge ends of the board, processes efficiently and effectively improves the processing quality.

Minimum spacing between pieces 500mm.

DOUBLE EDGING UNIT

First roughing unit and second fine profiling unit.

Each group consists of 2 independent high frequency motors. Each motor is equipped with large diameter vertical rotating copying devices and horizontal conical copying devices for perfect profiling.

4 MOTOR ROUNDING GROUP - MAXIMUM SPEED 23m/min

Allows the automatic rounding of the applied edge angles, at a speed of 23m/min, this rounding device has the following main features:

- Vertical and front copiers with ground contact surfaces for maximum precision in the work.

- Two-position work changeover system: Optimal finishes, with the ability to adapt to different board profiles without special adjustments or programming of the device.

DOUBLE SPOKE SCRAPER UNIT

For perfect finishing of PVC-ABS edges up to 3mm, eliminating all edge undulations. Automatic positioner from the control panel with the possibility to change two edge sizes.

FLAT TAIL SCRAPER UNIT

Upper and lower tail scraper group.

Equipped with large diameter feeler discs.

SWARF REMOVAL UNIT

Pneumatic clamp. This group traps the excess edge strip that has not been completely removed in the previous groups and prevents it from continuing towards the edge polishing group, favouring a better finish.

CLEANING SPRAYS

Cleaning fluid. By applying the cleaner before the cloth polishing discs, the previously applied release agent and loose glue residues are removed.

DOUBLE PULECANTOS GROUP

Composed of 2 independent motors of 0,18kW working at 1400 RPM for easy cleaning and shining of the edge.

Technical Data

THE MANUFACTURER RESERVES THE RIGHT TO MAKE CHANGES WITHOUT PRIOR NOTICE.

The technical data and characteristics mentioned in this offer are of an informative nature and may be subject to modifications, updates and improvements.

Videos

Documents

Our machines

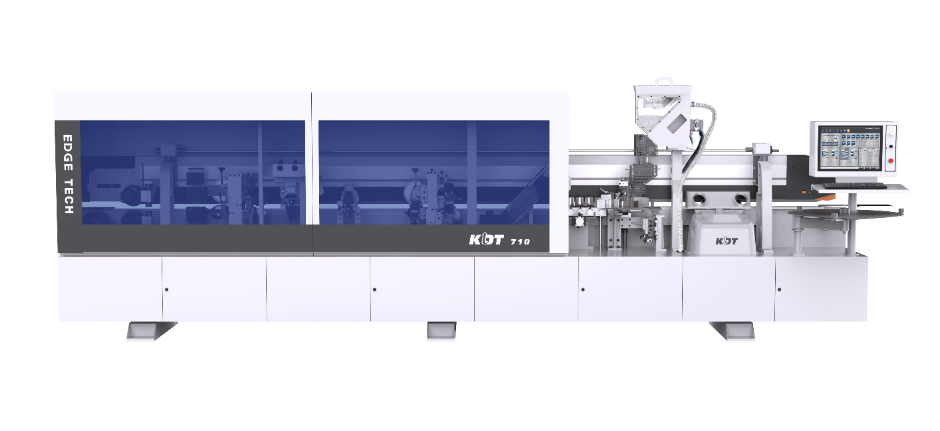

Edge banding machine KE-710BT

Gluing machine KE-268JSA

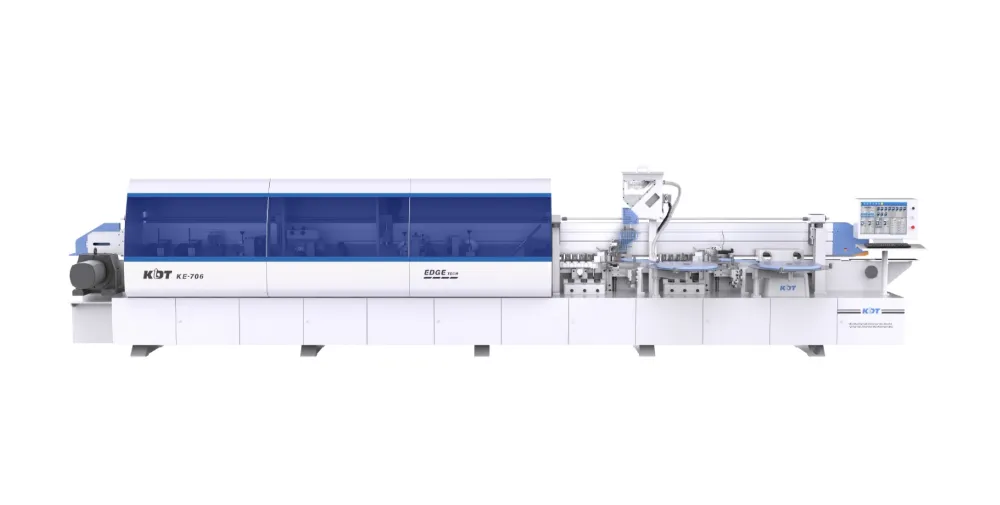

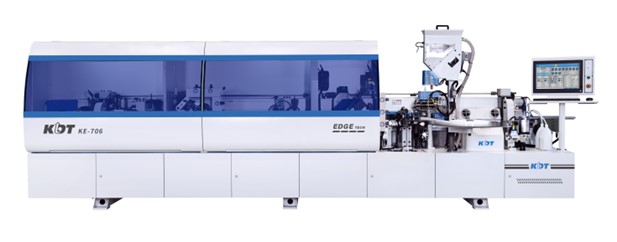

Single-side gluing machine KE-706GBSU Laser

Single-side gluing machine KE-706GB

Single-side gluing machine KE-706 CNC

Single-side gluing machine KE-668JSGAU (45)

Single-side gluing machine KE-668JGB

One-side gluing machine KE-665JSKA

Single-side gluing machine KE-665JHSKA

One-side gluing machine KE-655JSKA

Single-side gluing machine KE-526G

Single-side gluing machine KE-520GU

Single-side gluing machine KE-496GH

Single-side gluing machine KE-493G (40)

Single-side gluing machine KE-493 (40)