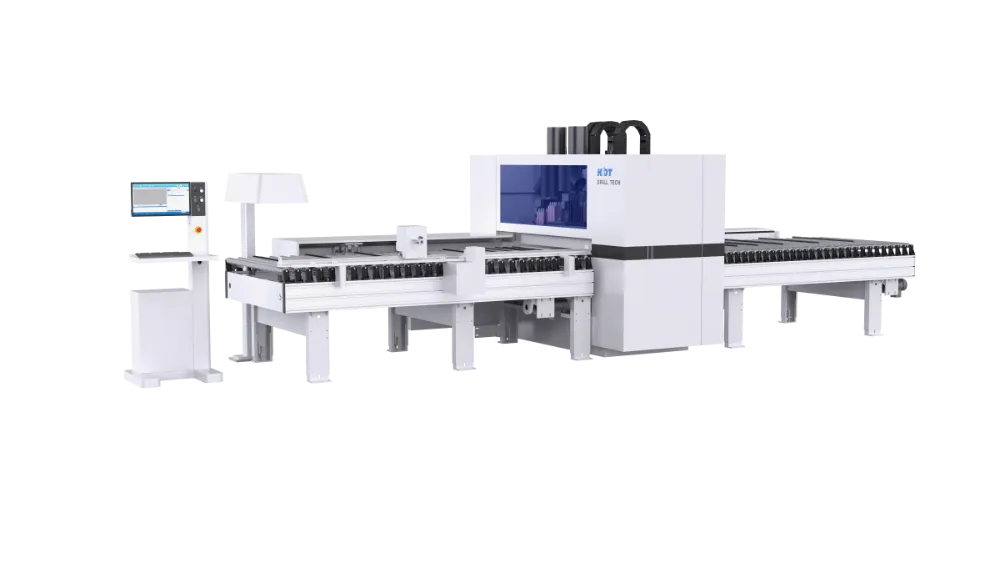

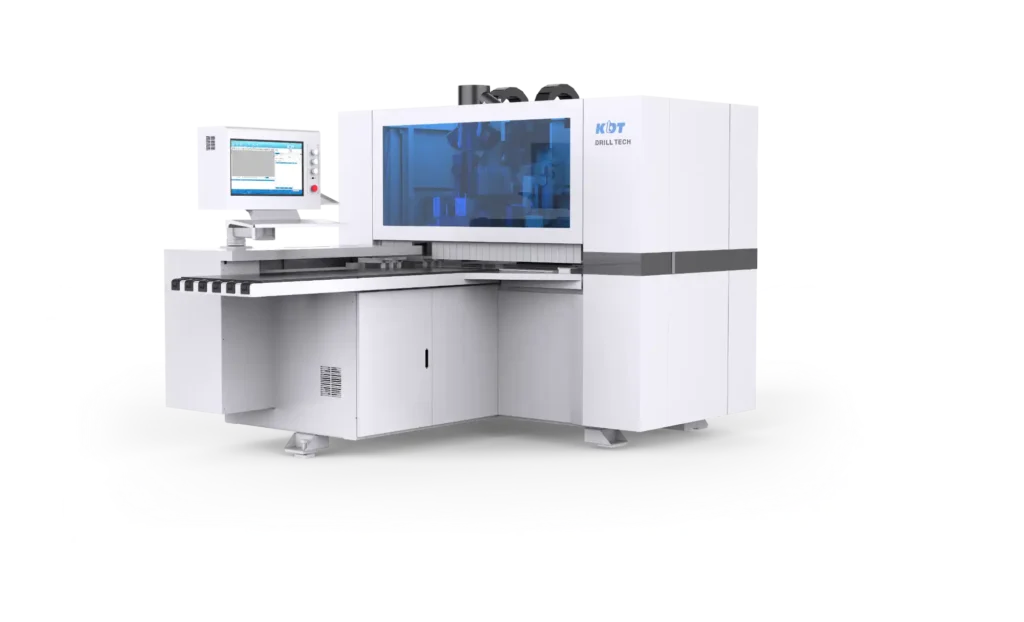

CNC Drilling

CNC drills: precision and efficiency for your work

In the industrial sector, the demand for precise and efficient machinery is essential to optimise production processes. Our CNC drilling machines are advanced solutions for businesses and professionals who work with different types of wood panels such as chipboard, MDF or melamine.

Thanks to their numerical control technology, they allow high speed and precision to be achieved in all their work groups, such as drills and milling machines, ensuring impeccable finishes on each piece.

Applications in the wood and other materials industry

The CNC wood drilling machines are indispensable in sectors such as furniture manufacturing and the production of decorative panels. Their versatility allows them to work with boards of different thicknesses, adapting to the needs of each customer.

They are used in the production of cabinets, kitchens, doors, modular furniture and architectural elements. Thanks to their milling capacity, they allow making decorative details and complex grooves.

Numerical control technology in industrial drilling machines

The operation of the CNC drilling combines advanced software and numerical control with a high-precision mechanical structure to program and execute precise movements in the drilling process.

Through the control computer, exact measurements can be established to ensure uniformity and quality in every borehole. This technology makes it possible to carry out drilling, milling and slotting in a variety of materials.

CNC multi-drilling for higher productivity

The drilling units of the CNC machines allow for simultaneous perforations at different points in the materialThis technology is ideal for companies looking for speed without compromising on finishing quality. This technology is ideal for companies looking for speed without compromising the quality of the finish.

CNC drilling centres: power and higher speed

The CNC drilling centre integrates advanced drilling, milling and grooving functions, optimising each manufacturing process. Its particular design allows it to automatically adjust to the different dimensions of the parts according to the production needs, ensuring precise results in each manufactured part.

CNC Drilling: key features

Each CNC drilling machine is designed to suit different industrial production needs. Some of its main features are

- Powerful vertical milling motors for milling on both sides of the panel.

- Top and bottom drilling units for drilling on both top and bottom faces and heads.

- Grooving saw unit on upper head for grooving.

- Numerical control and advanced software for total process control.

Advantages of CNC drilling in industrial production

The use of numerically controlled drills has significant advantages in the industrial environment. Some of them are:

- Connection to production lines

- Reduction of errors through computer-aided design.

- Increased production speed.

- Faster simultaneous drilling operations possible.

- Adaptability to a variety of drilling jobs.

- Greater efficiency in the use of materials.

The best choice for industry

KDT Ibérica's CNC drills are a high-performance solution for companies that require industrial machinery with advanced technology.

Their combination of precision, speed and efficiency makes them an ideal choice for the manufacture of any type of furniture, be it kitchens, bathrooms, wardrobes or modular furniture.

With a robust design, numerical control management and high-capacity work groups for milling, slotting and drilling, these machines ensure that all machining processes are optimised and superior quality results are achieved.