Machines for carpentry

Woodworking machines: a guide to choosing the ones you need

In a professional woodworking workshop, woodworking machines are a strategic investment. The right choice determines production capacity, finishing accuracy and profitability of the business. Well-selected equipment not only streamlines processes, but ensures consistent results that meet the highest industry standards.

Types of industrial woodworking machines and their uses

Industrial woodworking machines are classified according to their function in the woodworking process. Knowing each category is key to setting up a productive and efficient workshop.

Cutting machines

Designed for dividing, sizing and initial shaping of raw material.

- Table saw: makes straight and precise cuts in panels and strips. Essential for mass production.

- Sliding table sawallows for square and angled cuts, ideal for large format boards.

- Band sawVersatile for curved, irregular cuts and thick workpieces.

- Mitre sawfor fast cut-to-length cutting of slats, beams and profiles.

Machining and moulding machines

They work the wood to obtain specific profiles, grooves and shapes.

- Spindle moulder or table routercreates mouldings, recesses and recesses with high precision.

- CNC milling machine for woodAutomates complex cuts and engravings with millimetre accuracy.

- Multi-drill: drills several positions at the same time, ideal for modular furniture.

Brushing and surface finishing machines

They achieve flat, uniform surfaces ready for final finishing.

- Planerremoves irregularities and prepares the wood for assembly.

- Thicknesser: adjusts the thickness of the boards exactly.

- Belt sander: offers continuous and fast sanding on large surfaces.

- Calibrating sander: used in industrial production for homogeneous finishes.

Assembly and joining machines

Optimises the assembly of parts and guarantees strong joints.

- Hydraulic press: clamps and glues workpieces with uniform pressure.

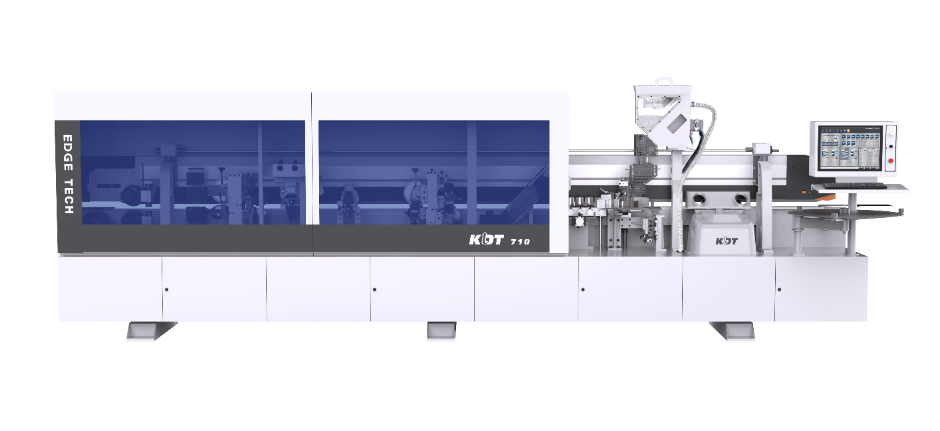

- Edge banding machine: applies and fixes edges on boards quickly and cleanly.

Key factors in choosing a woodworking machine

Selecting the right woodworking machines is not just a question of price; it is a decision that has a direct impact on productivity, the quality of the end product and the profitability of the workshop. These are the most relevant criteria to evaluate:

- Type of production: Industrial production: requires robust, high-capacity machinery designed for continuous use.

- Capacity and powerEngine power and cutting or machining capacity determine efficiency. An undersized machine will slow down production and increase wear.

- Precision and stabilityHigh-quality finishing requires stable tables, adjustable slides and fine calibration systems. On CNC machines, micron tolerance is a critical factor.

- SecurityIn professional environments, safety is not optional: emergency stop systems, transparent and adjustable guards, anti-rebound technology and recoil control and proximity sensors on latest generation models.

- Ergonomics and ease of useOperators work long hours on these machines, so the design must minimise fatigue and allow for quick adjustments.

- Maintenance and spare parts availability: Opting for brands with local technical support and immediate parts availability avoids prolonged downtime that affects production.

- Energy consumptionIn continuous production, electricity consumption has a direct impact on operating costs. Machines with energy-efficient motors are a long-term investment.

- Integration into the workflow: Consider how the machine will fit into the workshop layout, material flow and compatibility with other tools or production lines.

Tips for optimising your woodworking machines

Good equipment is only the first step; its performance and service life depend on proper management. Implementing optimisation practices in the use and maintenance of woodworking machinery ensures consistent results, reduces costs and avoids unnecessary downtime.

Preventive maintenance programme

- Periodic inspections should be carried out in accordance with the manufacturer's instructions.

- Replace blades, saws and cutters before they lose their sharpness to maintain accuracy and avoid motor overload.

- Cleans dust and resin build-up to prevent overheating.

2. Sharpening and calibration

- Keep cutting tools sharp with specialised services or in-house sharpening systems.

- Checks the alignment of guides, tables and stops to ensure straight and accurate cuts.

3. Staff training

- Ensure that operators are familiar with the operation, limitations and safety measures of each machine.

- Train in the efficient use of materials to reduce waste.

4. Lubrication and wear control

- Apply recommended lubricants at friction points to avoid premature wear.

- Checks bearings, belts and gears, replacing parts before critical failures.

5. Dust and chip management

- Install industrial vacuum systems to protect the health of workers and extend the service life of machinery.

- Clean filters and tanks regularly to maintain suction power.

6. Workflow optimisation

- Locate each machine according to the production sequence to minimise unnecessary movements.

- Combines fixed and portable machinery to increase operational flexibility.

7. Consumption control

- Monitors the electrical consumption of each machine to detect inefficiencies.

- Evaluates the replacement of old equipment with more energy-efficient and efficient models.

Frequently asked questions about woodworking machines

What woodworking machinery is essential in a professional workshop?

The basics include table saw, planer, thickness planer, shaper, belt sander and drill press. Depending on the type of production, CNC routers, presses and edgebanders can be added.

What is the best woodworking machine for cutting solid wood?

The band saw is ideal for cutting thick solid wood, while the table saw offers greater precision for straight and repetitive cuts.

What is the difference between a planer and a thicknesser?

The planer smoothes the surface of the wood and corrects irregularities, while the thicknesser adjusts the thickness of the boards evenly.

How to keep woodworking machines in good condition?

Daily cleaning, regular sharpening of blades and discs, lubrication of moving parts, and periodic checking of alignments and safety systems are recommended.

Is it worth investing in CNC woodworking machinery?

Yes, in industrial production or high-precision work, CNC machinery improves speed, reduces errors and allows complex designs with millimetre tolerances.

Servicios, apoyo técnico y acompañamiento profesional

En KDT Portugal, no somos solo proveedores de máquinas. Nuestra empresa acompaña a los clientes en todo el proceso, desde la elección del equipo hasta su integración en la línea de producción.

Ofrecemos servicios de apoyo técnico, formación y asistencia, garantizando que las máquinas de carpintería funcionen de manera eficiente y segura. Este acompañamiento es esencial para las empresas que buscan maximizar la inversión y asegurar un rendimiento continuo de los equipos.

Nuestro compromiso con los clientes se basa en la cercanía, el conocimiento técnico y la capacidad de responder a las necesidades reales de cada proyecto.

Carpintería en Portugal: soluciones para el mercado actual

El mercado de la carpintería en Portugal sigue creciendo, impulsado por la demanda de muebles personalizados, proyectos de diseño y producción industrial de calidad. Las empresas del sector necesitan soluciones fiables que les permitan crear productos competitivos y adaptados a las exigencias del mercado.

Las máquinas para carpintería de KDT Portugal han sido desarrolladas para responder a estas necesidades, ofreciendo soluciones industriales pensadas para la producción profesional, ya sea en pequeños talleres o en grandes empresas.

Nuestra presencia en el mercado portugués refleja el compromiso de proporcionar tecnología, calidad y soporte continuo a los profesionales de la carpintería.

Elegir KDT para su carpintería profesional

Elegir KDT significa apostar por una empresa especialista en soluciones para carpintería industrial. Trabajamos con máquinas de carpintería diseñadas para generar un valor real en la producción, mejorar los procesos y garantizar calidad en cada proyecto.

Ya sea para fabricar muebles, puertas o piezas a medida, nuestras soluciones se adaptan a sus necesidades y a su espacio de trabajo. KDT Portugal pone a disposición de sus clientes tecnología avanzada, servicios especializados y un enfoque orientado a resultados.

Si busca carpintería con soluciones industriales, máquinas profesionales y apoyo técnico dedicado, KDT es el socio ideal para su proyecto en madera.