Woodworking machinery

Woodworking machinery: types, uses and selection criteria

Looking to optimise your woodworking? The right choice of machinery can make a big difference to your projects. In this guide we detail everything you need to know about woodworking machines, from basic equipment to advanced industrial solutions.

Without a doubt, wood-cutting machinery boosts workshop productivity.

Types of industrial woodworking machines

Woodworking machinery is classified according to its main function. Each type responds to the specific needs of working with this material.

Combined machines, for example, integrate several functions in a single machine, saving space and resources. Here are some of the most important ones:

Drills

Specific drills for carpentry allow you to drill holes with great precision. Their versatility and adaptability make them indispensable allies for both amateurs and professionals in the sector.

Squaring machines

Sliding table saws are essential for right angle cutting and panel production. They are a practical solution for workshops that need to perform precise cutting of panels.

Sanders

Sanding machines speed up the finishing process. There are orbital, belt or disc models, each adapted to different needs.

In addition, KDT sanding machines are equipped with an internal suction system and blowers to promote perfect finishes and ensure the durability of the belts, all of which helps to reduce the maintenance of the machines.

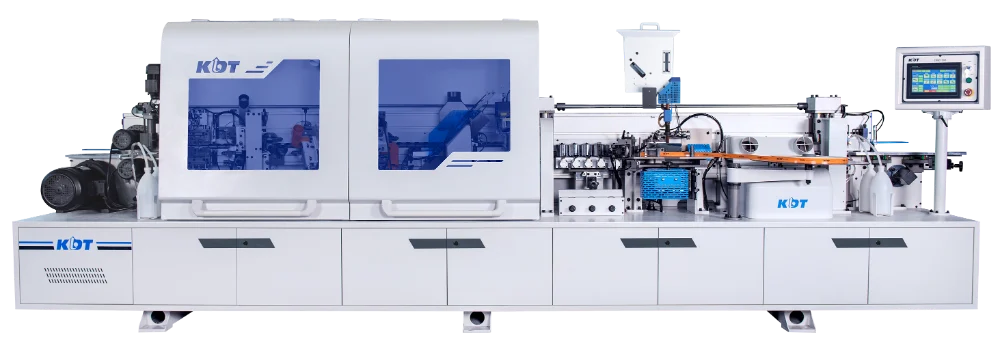

Disconnectors

High production industrial cutting machines. Controlled by industrial PC to load the cutting lists and carry out all the jobs automatically. These lists can be designed on the machine itself or in the office.

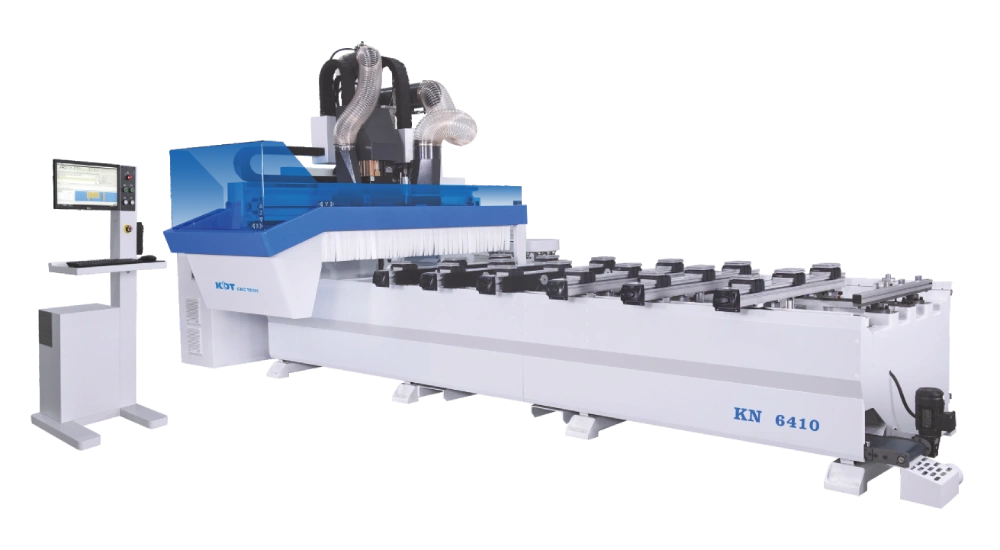

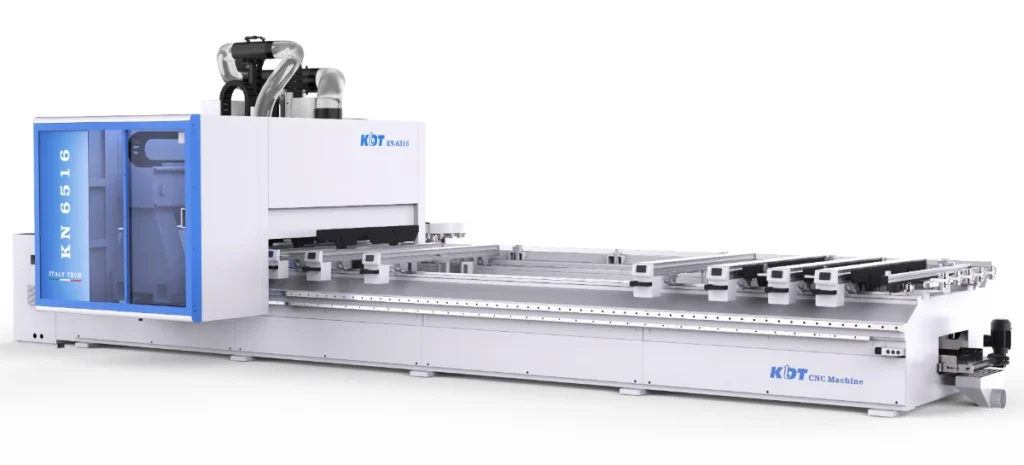

Machining centres

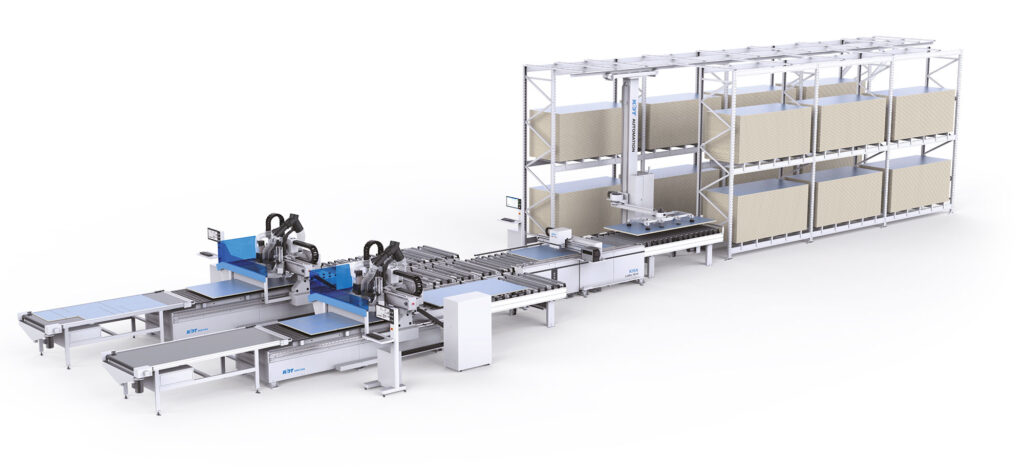

With a nesting or aluminium bar table, the machining centres offer a high versatility of work by being able to combine panel cutting with drilling, slotting and grooving, depending on the different designs, which are loaded directly into a computer. With an intuitive and simple interface, designs can be made in the office and uploaded to the machine, which carries out the work automatically and at high speed.

CNC woodworking machinery: digital precision

The digital revolution has arrived in carpentry with CNC (Computer Numerical Control) machines. This woodworking machinery allows automate complex processes with millimetre precision.

CNC machining centres perform multiple operations without the need to reposition the workpiece. They include interchangeable tools for milling, drilling and cutting.

For example, CNC milling machines work on customised panels according to digital designs. They can carry out complex jobs with perfect repeatability, ideal for series production.

Criteria for selecting woodworking machinery

Choose the woodworking machinery is a key decision that directly impacts the productivity, the quality of the final work and the profitability of a workshop or industry.

Not all woodworking machines They serve the same purpose, and not all environments have the same needs. It is therefore important to consider certain key factors before making an investment.

Volume of production

The first step is to determine how many parts are to be produced and how often.

- Professional carpentriesProfessional woodworking machinery that combines performance with precision is required. Here it is common to have sliding table saws, planers, sanders and vacuum systems to keep the workspace clean.

- IndustryThe high volume of production requires industrial woodworking machinery, such as CNC machining centres, automatic cutting machines, roller feed systems and complete production lines. This equipment is designed to work continuously and accurately over long periods.

2. Available space

The dimensions of the workspace directly influence the type and number of machines that can be installed.

- Some woodworking machines require additional space not only because of their size, but also because of the movement of the parts during handling.

- For small spaces, it is advisable to opt for adjustable machines, with extendable or folding tables, or by equipment that integrates several functions in a single unit.

3. Level of accuracy required

Not all woodwork requires the same level of detail.

- In structural carpentry or construction projects, a circular saw of good quality can be sufficient for fast and efficient cuts.

- However, in customised furniture manufacture, the following is required carpentry machinery that guarantees clean cuts, perfect joints and smooth surfaces.

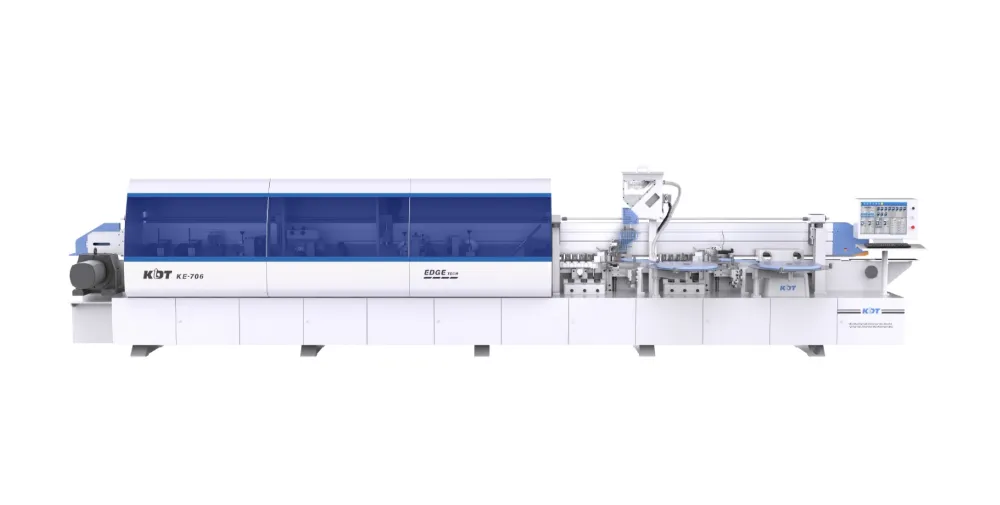

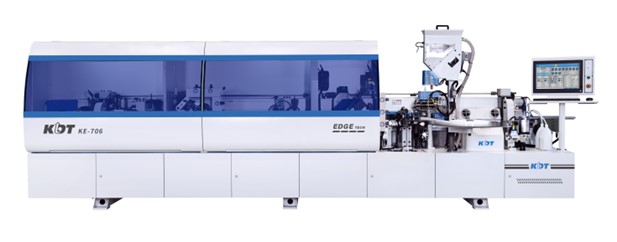

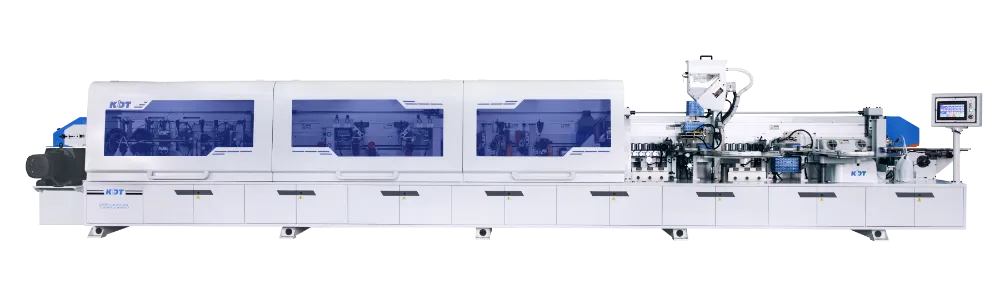

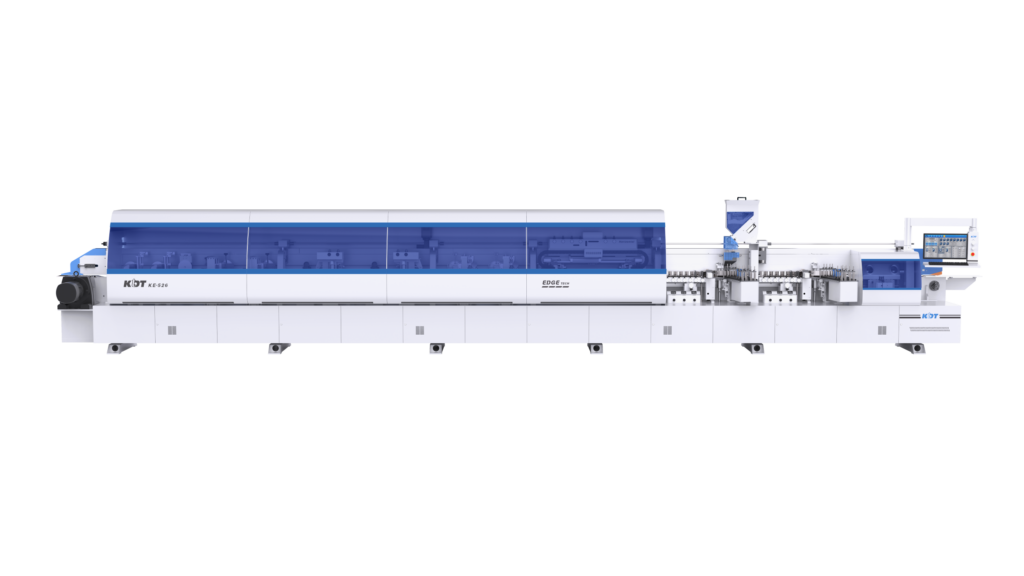

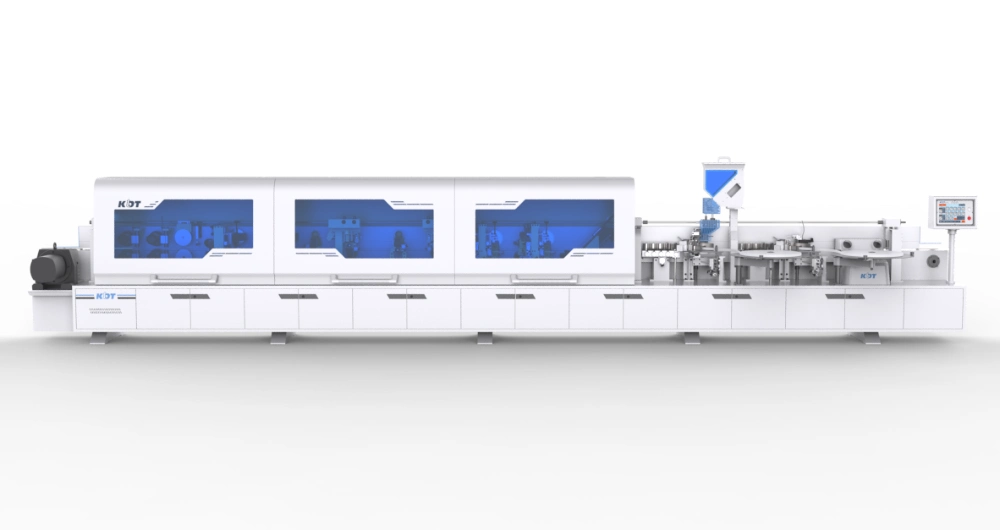

Industrial woodworking machinery for sale at KDT Ibérica

To have the carpentry machinery The right equipment makes the difference between slow, limited work and agile, precise, professional work. Whether you work in a small craft workshop or in a high volume industry, choosing the right equipment is critical to achieving an efficient, safe and high quality workflow.

At KDT Ibérica, we are specialists in industrial woodworking machinery, and our aim is to help you find exactly what you need for your project. Contact us now for fully personalised advice.