Automation

What are machining centre drives?

The automation systems for machining centres include systems designed to automate repetitive tasks and optimise the operation of CNC machines in manufacturing processes.

Their main function is to reduce human intervention, increase accuracy and improve production times and processes. These systems can control everything from the loading and unloading of parts to the programming of complex operations.

In the industrial sector, where efficiency and competitiveness are key, implementing automation allows companies to adapt to higher production demands without compromising quality.

Benefits of implementing automation systems for machining centres

Applying automation in a machining centre brings direct benefits in terms of both productivity and profitability:

- Reduction of downtime: Process automation eliminates waiting times between tasks and optimises workflow.

- Improved accuracy: By minimising human intervention, the margin of error is reduced and repeatability of operations is ensured.

- High performance: Automated systems make it possible to maintain continuous production, even outside working hours.

- Reduction of operating costs: Less reliance on operators for routine tasks and better use of available resources.

- Increased security: Human errors that could compromise both machine and personnel are avoided.

Most common types of automatisms used in machining centres

Depending on the type of work and the desired level of automated production, there are different automation solutions for machining centres:

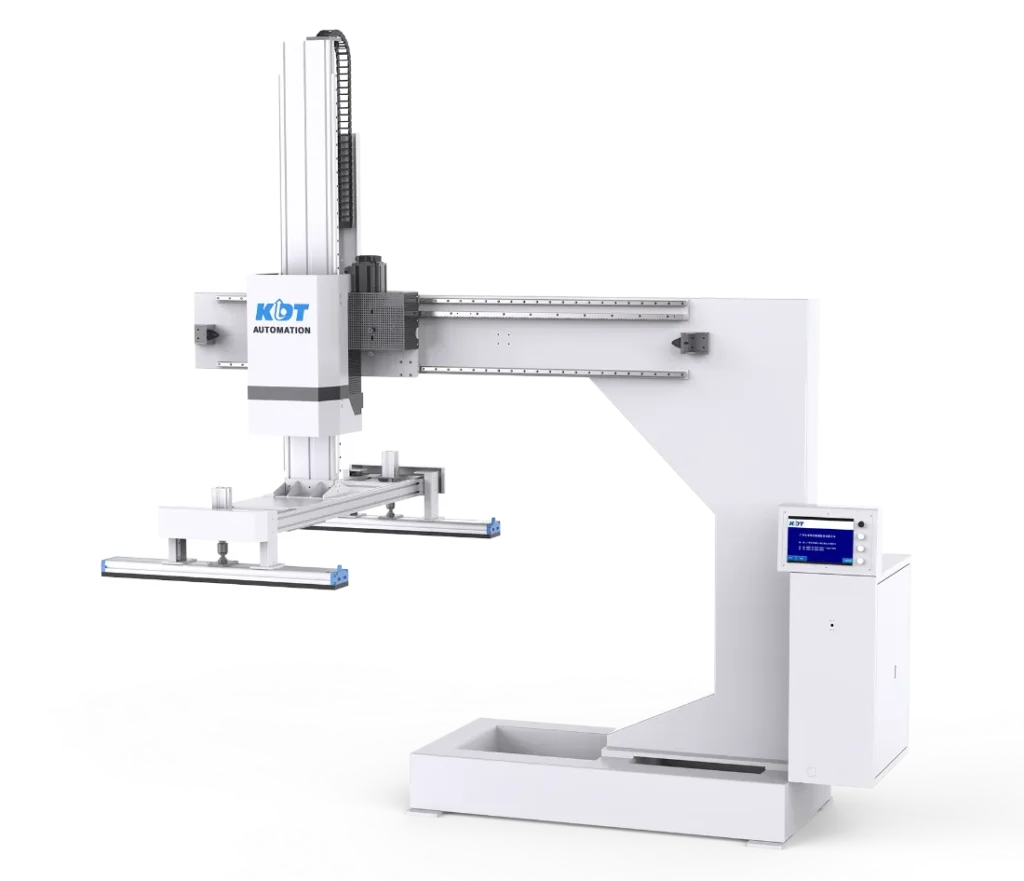

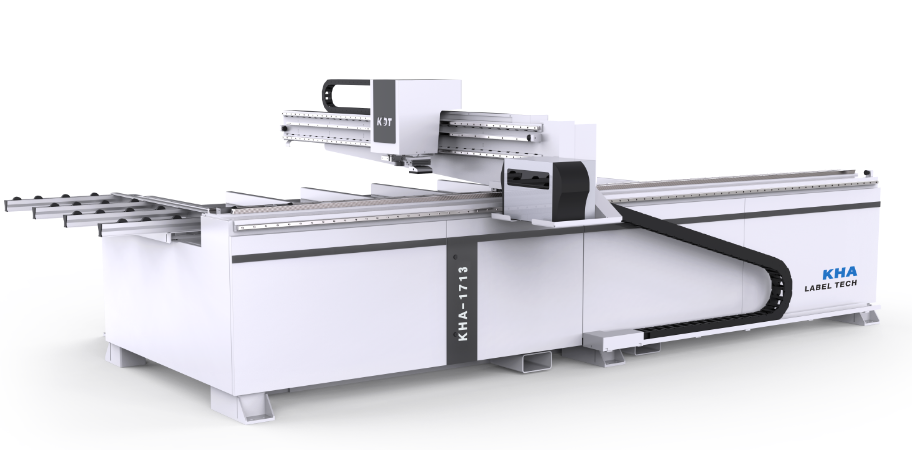

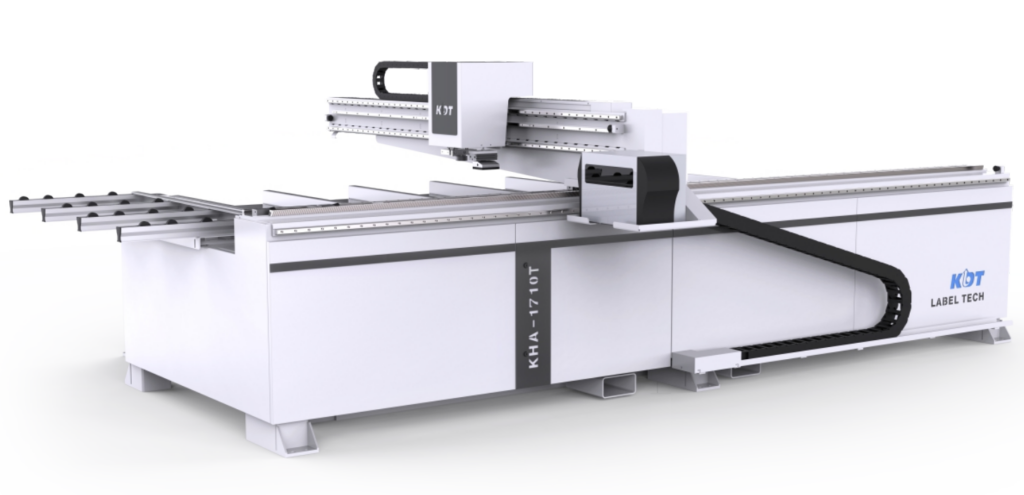

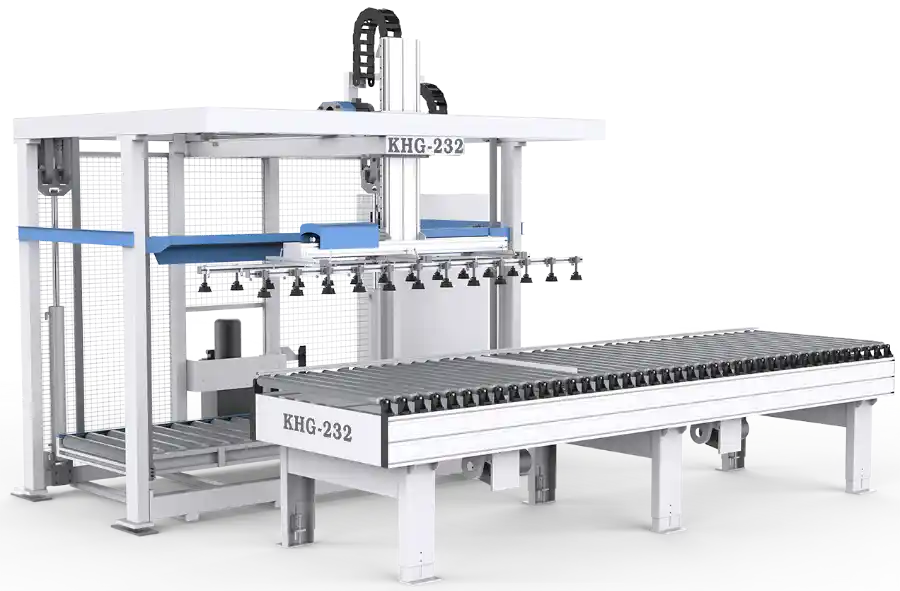

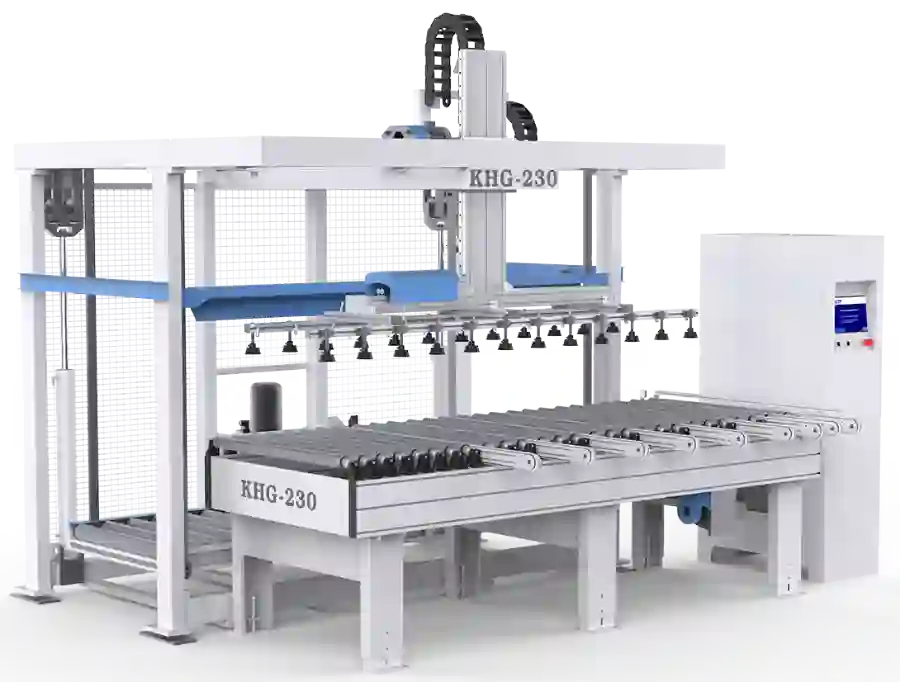

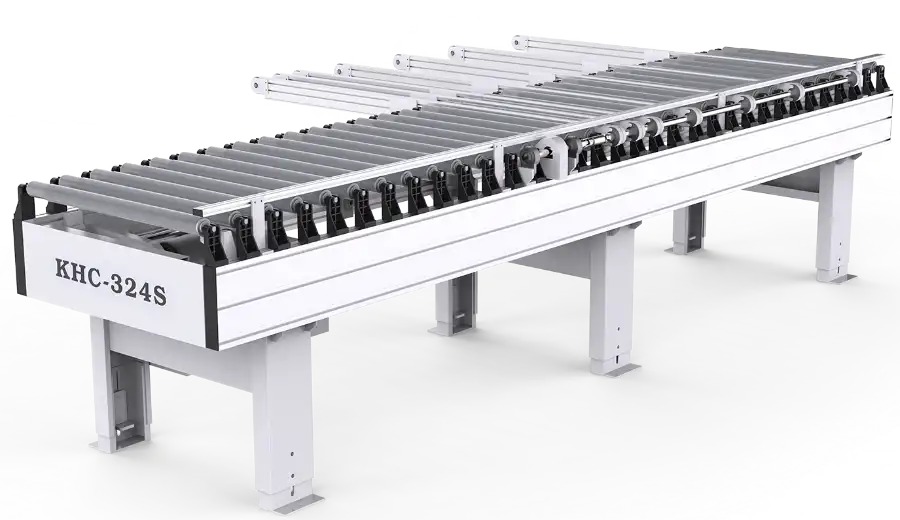

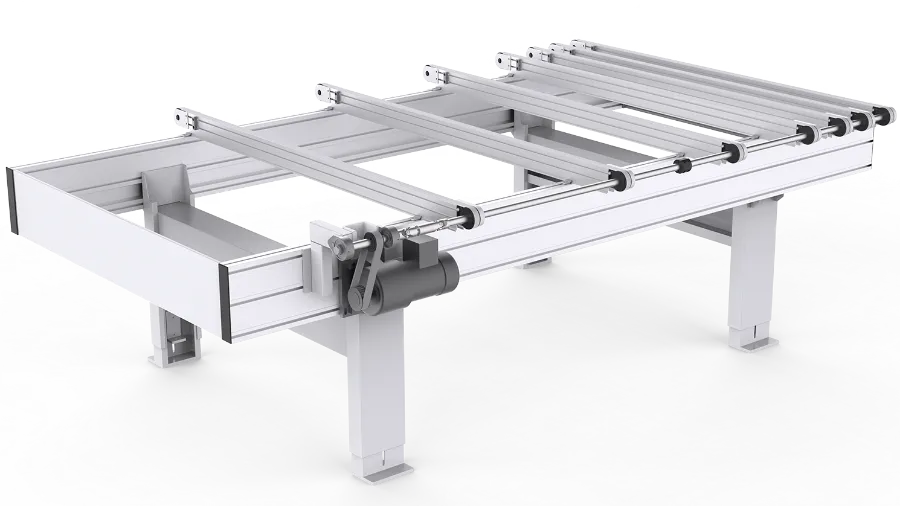

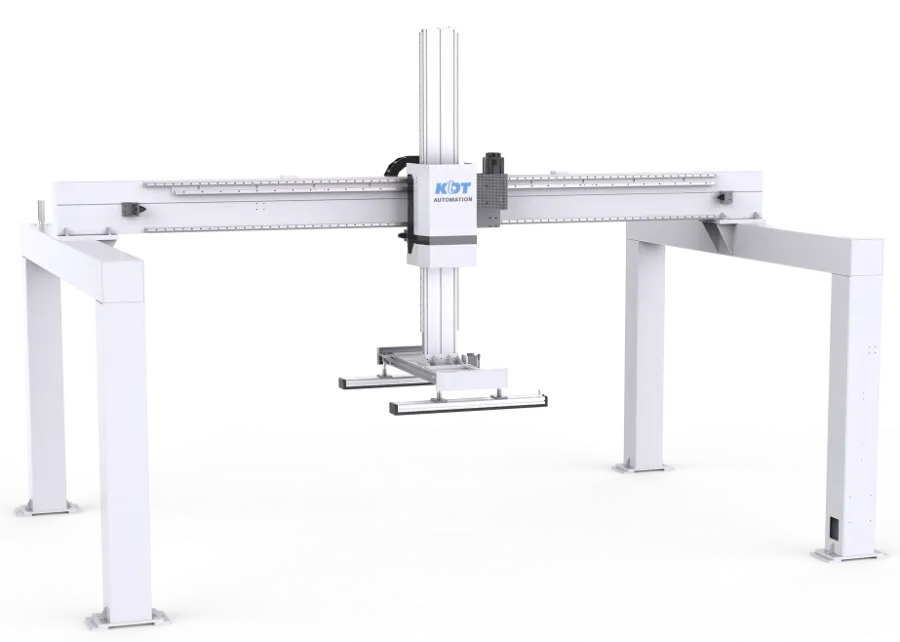

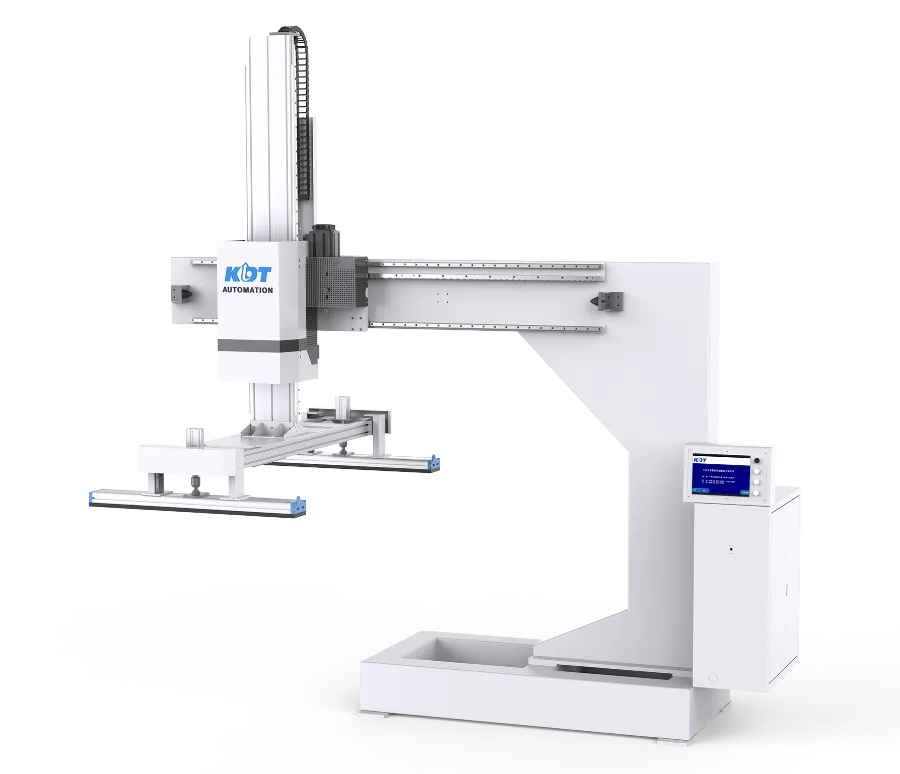

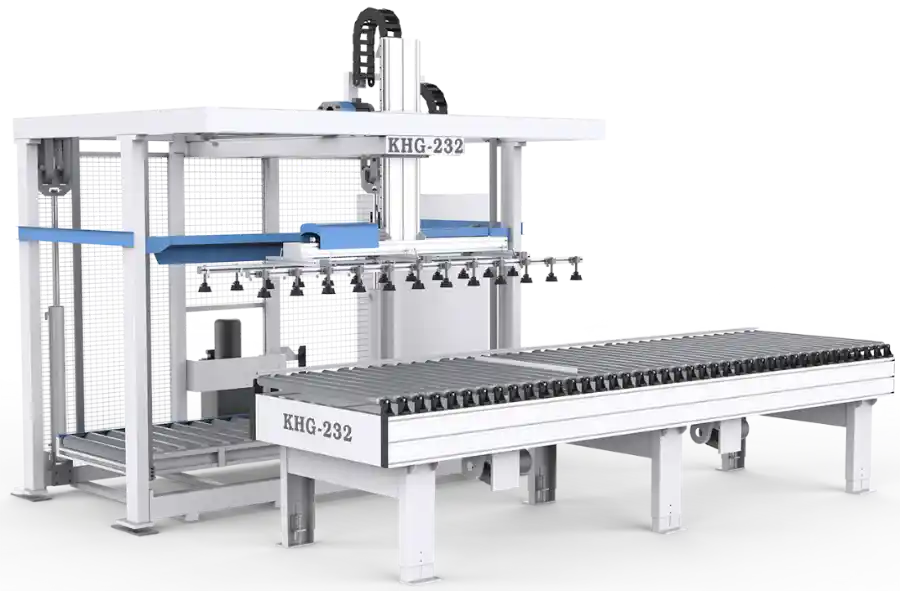

1. Automatic loading and unloading systems

They use robotic arms or sliding tables to insert and remove parts from the machining centre without manual intervention. This type of automation is essential in continuous production lines or long series.

2. Automatic Tool Changers (ATCs)

Allow the machining centre to select and use different tools during the same cycle, without stopping production. They increase efficiency on jobs with multiple operations.

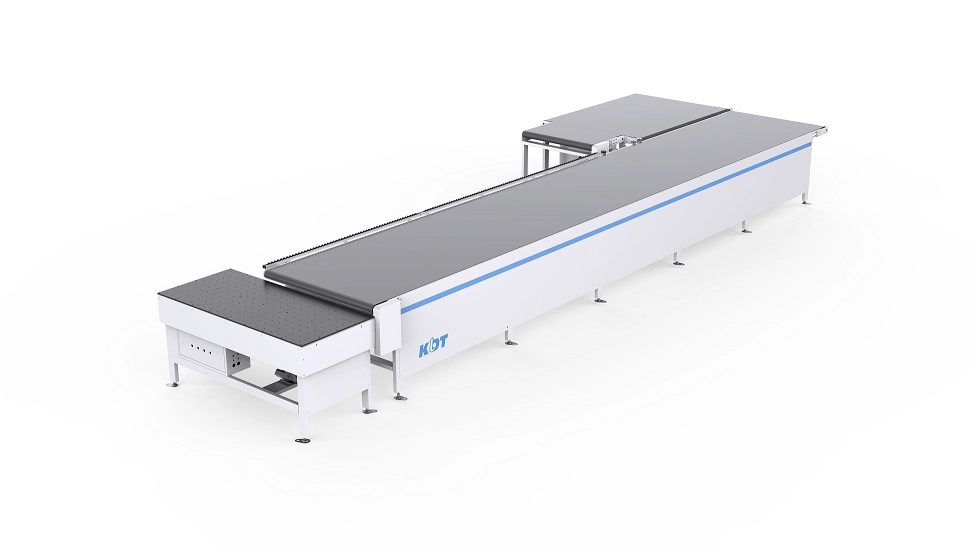

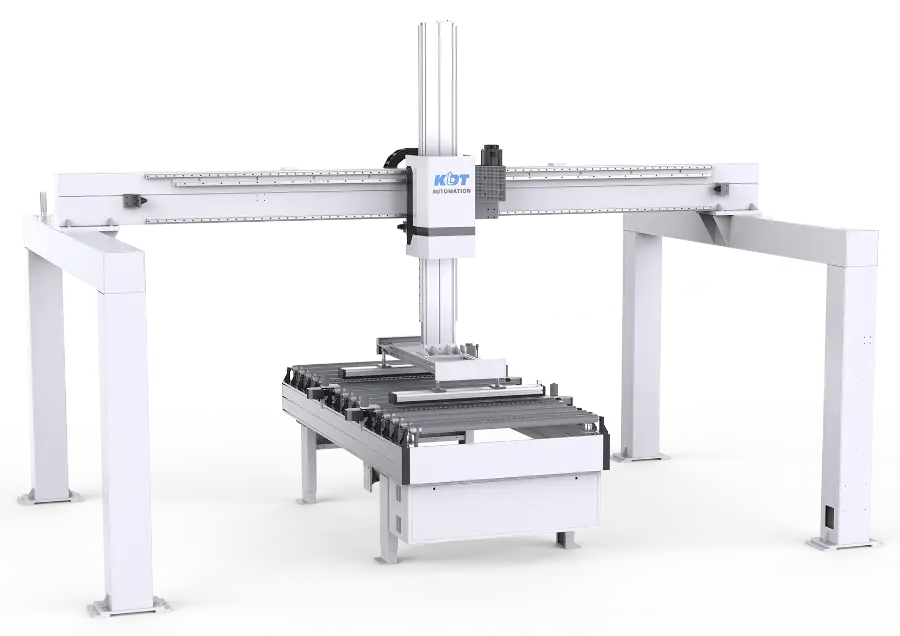

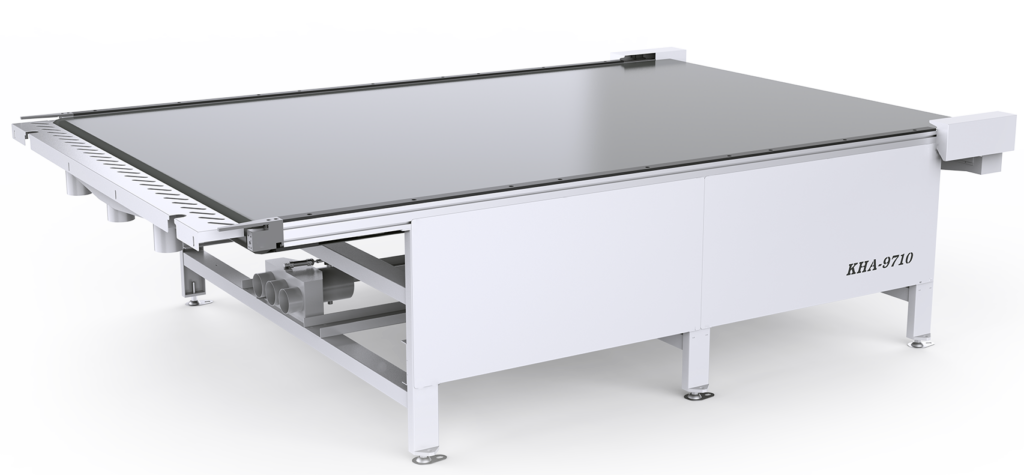

3. Automated warehouses

They integrate intelligent towers or racks to store panels of different sizes, thicknesses and materials, automatically managing inventory and internal logistics.

4. Remote monitoring and control systems

They allow machine parameters to be monitored and adjusted remotely, in real time. They improve traceability and allow faster intervention in the event of faults or incidents.

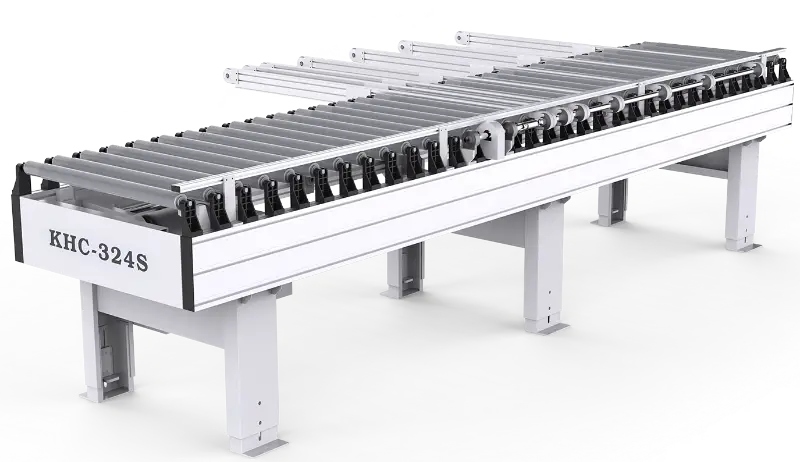

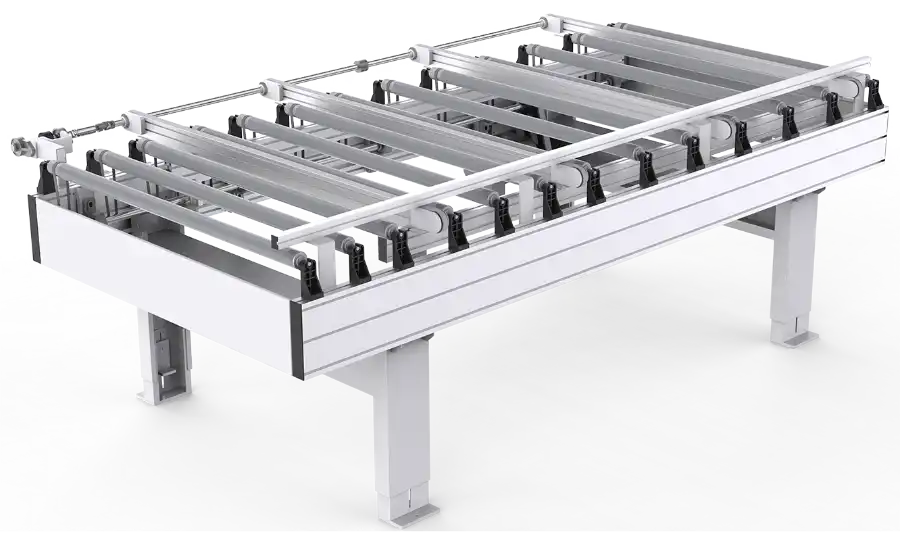

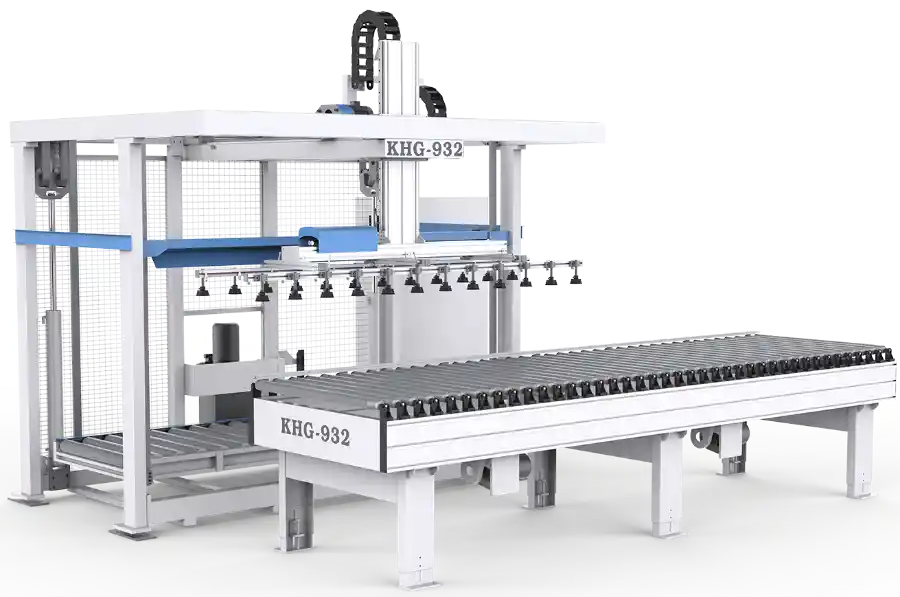

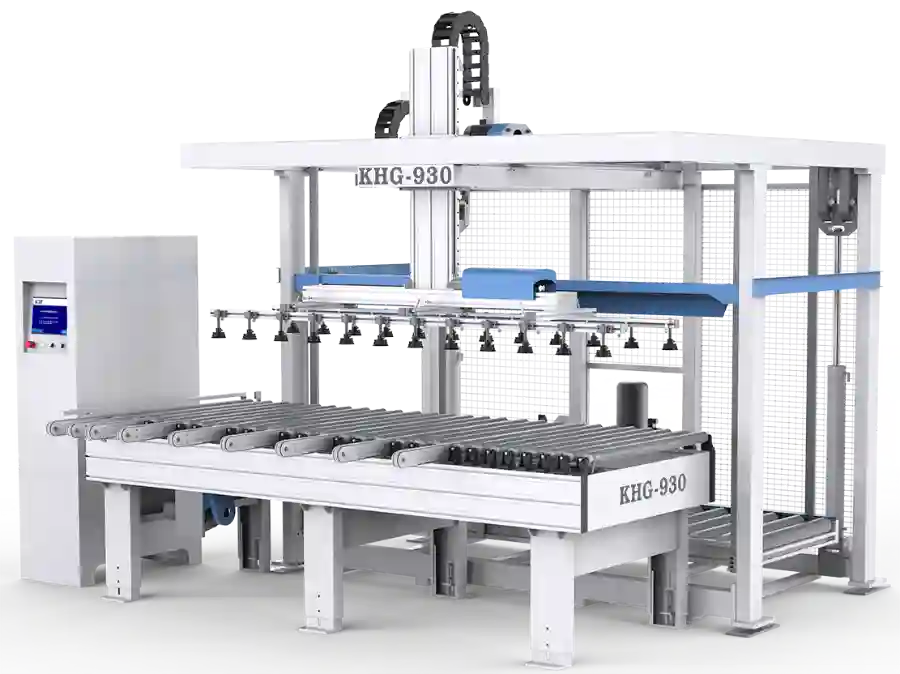

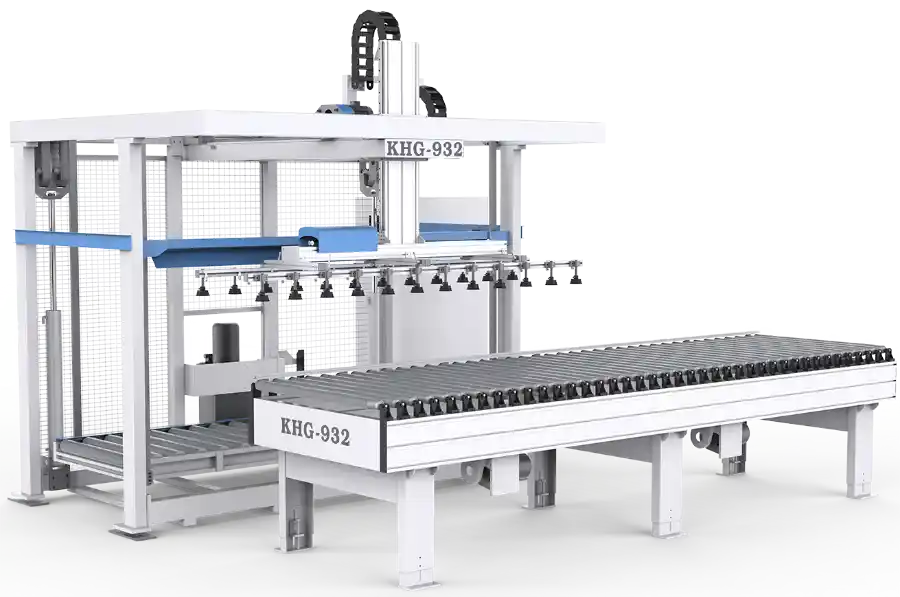

5. Door operators

Systems designed to automate specific door manufacturing tasks such as stacking, transport or handling of doors, optimising production and reducing handling times.

When should a machining centre be automated?

Machine automation is not exclusive to large industrial plants. In fact, more and more SMEs in the metalworking and manufacturing sector are implementing automation options for machining to:

- Reduce dependence on skilled labour.

- Increase productivity without extending shifts.

- Optimise resources for repetitive series or complex processes.

If your company is looking to scale up production capacity, improve product quality or reduce operating costs, automation can be a strategic investment.

Investing in industrial automation for machining centres not only improves the efficiency of the production process, but also represents a clear competitive advantage in today's market that translates into greater profitability and precision.

Are you considering automating your machining centre? Having a supplier specialised in machining machines will make a difference in the performance and durability of your systems. Take a look at all our options and contact us if you have any doubts.