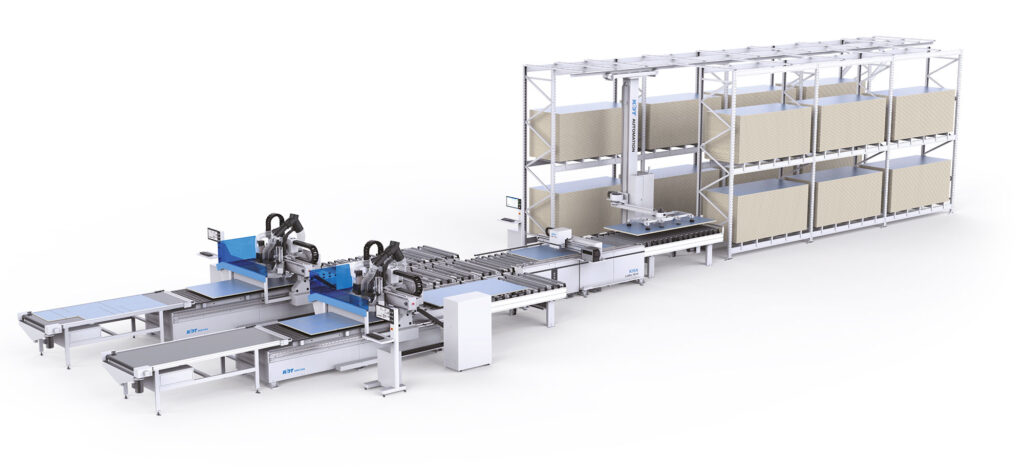

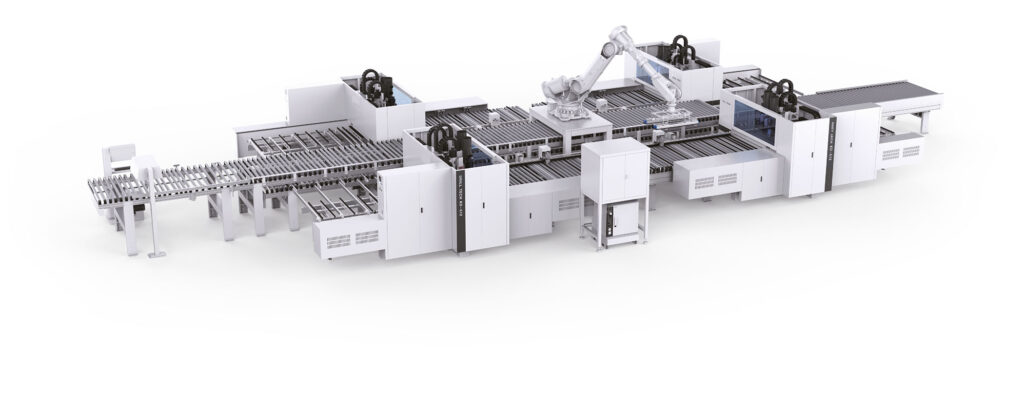

Flexible lines

Flexible assembly lines: the key to industrial automation

In today's manufacturing industry, marked by the rapid evolution of demand and the need to adapt to different market requirements, the implementation of flexible assembly lines has become a differentiating factor for companies seeking to optimise their production.

These lines represent a significant evolution compared to traditional production lines, providing flexibility and significantly improving productivity.

For production engineers, plant managers and operations managers, understanding the benefits and technology behind these solutions is critical to making strategic investments that will boost the growth and competitiveness of your company.

What are flexible assembly lines?

The flexible production lines are a system that allows you to quickly modify the configuration of the different workstations to optimise the available space to the maximum, favouring a more efficient workflow, saving time and making the most of the materials.

In contrast to the traditional lines, these solutions are characterised by their adaptability, allowing changes in the sequence of operations without the need to stop the process completely.

The flexibility of these lines is manifested in aspects such as:

- Adaptation to different production volumes

- Ability to manufacture several types of products on the same line

- Rapid reconfiguration of machinery and workstations

- Integration of CNC nesting technology

Benefits of implementing flexible lines

The adoption of flexible production lines brings with it numerous advantages that have a direct impact on the company's competitiveness.

These benefits make investment in flexible lines a strategic decision for any company seeking to remain competitive in today's industry.

Among the most important benefits are:

- Greater adaptability to changes in demand

Flexible lines allow production to adjust quickly to market fluctuations, reducing turnaround time and improving customer satisfaction. - Reduction of production times

Quick changeovers between different products minimise downtime, increasing overall production speed. - Improvement in final quality

The accuracy of automated systems and better control over processes significantly reduces errors. - Increased overall productivity

The combination of flexibility and high speed improves the overall efficiency of the manufacturing plant. The high productivity achieved with these flexible lines translates into increased competitiveness and profitability.

The future of production lies in flexibility

The adoption of flexible production lines is a key strategic investment for manufacturing companies seeking to improve efficiency, increase productivity and adapt to changing market demands.

The integration of advanced technology, such as cnc nesting and robotisation of some processes, together with careful planning and a focus on safety, allows production processes to be optimised. more agile and efficient.

At KDT Ibérica, we are committed to providing innovative solutions that drive flexible production for our customers, helping them to achieve a high performance and high speed on their manufacturing lines. Flexibility is no longer an option, but a necessity for improvement in modern industry.