Machined drill

CNC machining drills: technology, innovation and process optimisation

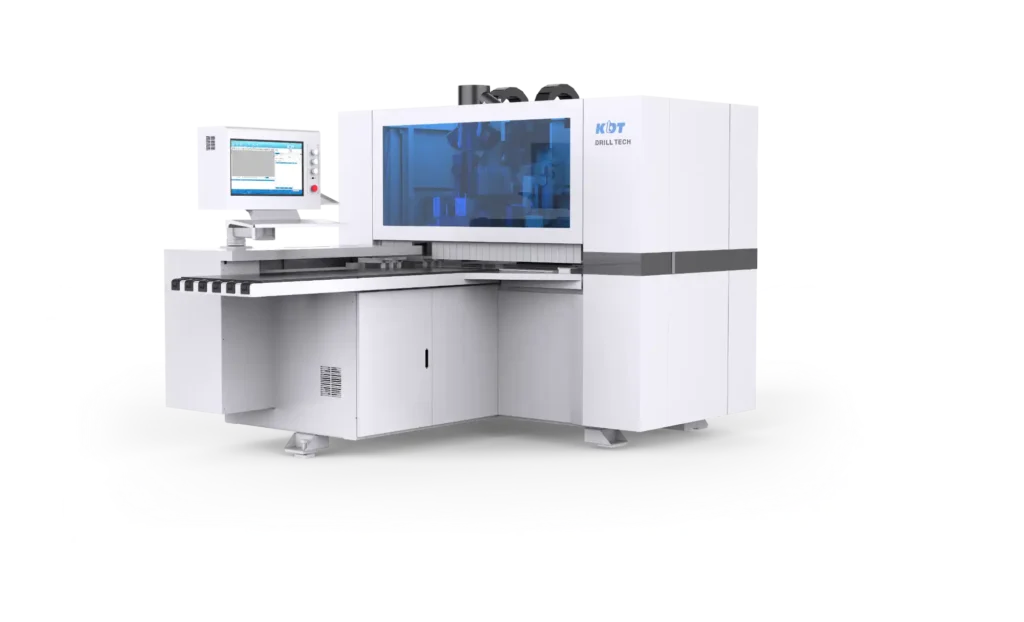

CNC drilling (Computer Numerical Controlled Drilling) has revolutionised drilling by automating the movements and parameters of cutting, milling, grooving and drilling. These machines allow complex drilling operations to be programmed with high precision, ensuring repeatability in production.

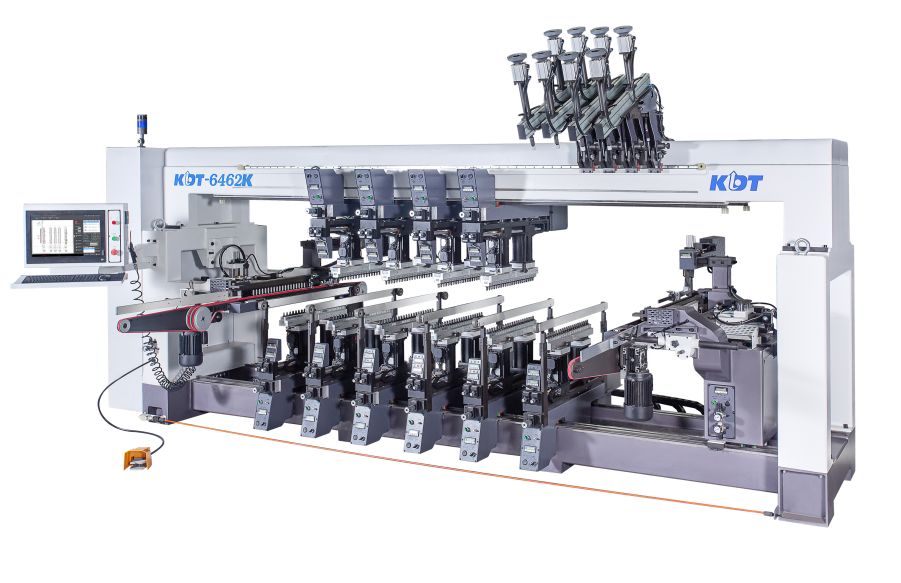

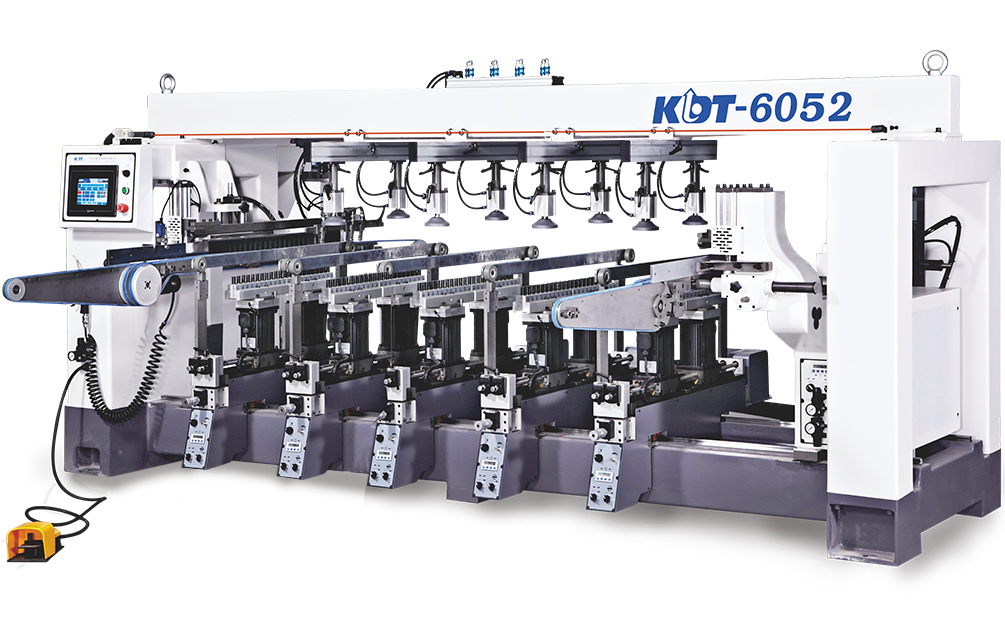

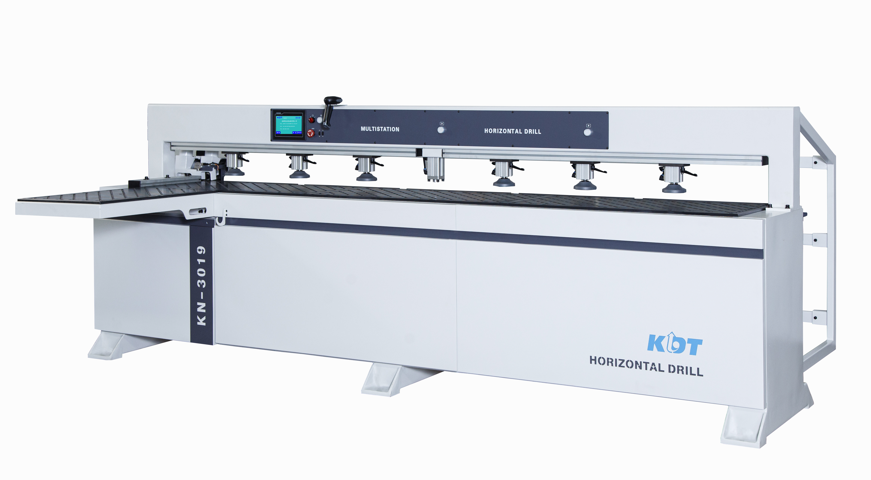

CNC machining drills and multi-drills are key tools in any industrial process. It is necessary for joining components, creating anchor points or even for specific surface finishes.

That's why advanced machines like the CNC drilling centres or multi-drilling machines are essential to execute operations with millimetre precision, optimising both productivity and finishing quality.

CNC drilling machining process

The drilling process consists of generating precise holes in the parts. During this operation, the drill bit rotates at high speed and penetrates the material to remove chips.

The efficiency of industrial drilling depends on factors such as drill rotation speed, feed rate and machine power. In addition, there are different types of holes, each with its own characteristic geometry and depth. The depth of the hole and the finish of the hole will depend on factors such as the machine power and material hardness.

To ensure quality drilling, it is important to select the right drill bit, set the correct rotational speed and feed rate, and consider the properties of the material to be worked. These practices ensure precise holes and a superior finish on machined parts.

Drilling tools: types of drill bits for CNC and multi-drill holes

The drill bit is the basic cutting tool for drilling holes in a workpiece. There are different types of drill bits, each adapted to different types of holes and materials.

Large diameter drills are used to create large holes, while small diameter drills allow small holes to be drilled with high precision. The geometry of the tip influences the centring and finishing of holes; for example, drills with a centring tip improve the quality of the hole.

For drilling deep holes, long drill bits and coolant systems are used for chip removal. It is important to choose the right type of drill bit depending on the hardness of the material and the depth of the hole to optimise process accuracy and productivity.

The impact of CNC drilling and machining on industrial productivity

The drilling operation with the right tools is a key process in modern industry. The combination of CNC technology with CNC drilling and multi-drilling configurations has increased productivity and accuracy in part manufacturing.

Proper selection of drill, drill bits and cutting parameters (power, speed and feed) according to the material and depth required is important for to obtain the desired finish. Mastering these aspects optimises hole quality and ensures efficiency in industrial machining.