Door machining

Door machining: CNC technology and precision for machining

Door machining has become an ally in the carpentry and construction industry. Gone are the traditional methods, making way for the CNC technology (computer numerical control), which allows work to be carried out with unique precision.

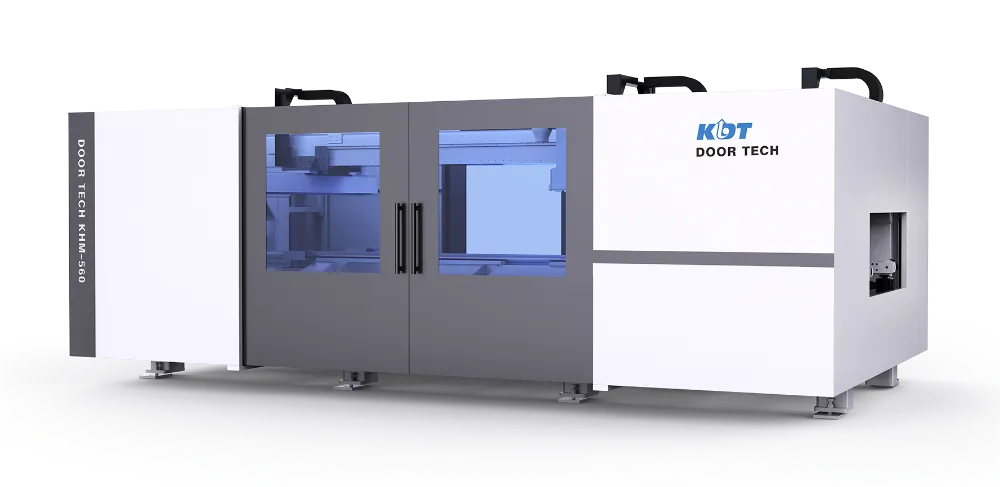

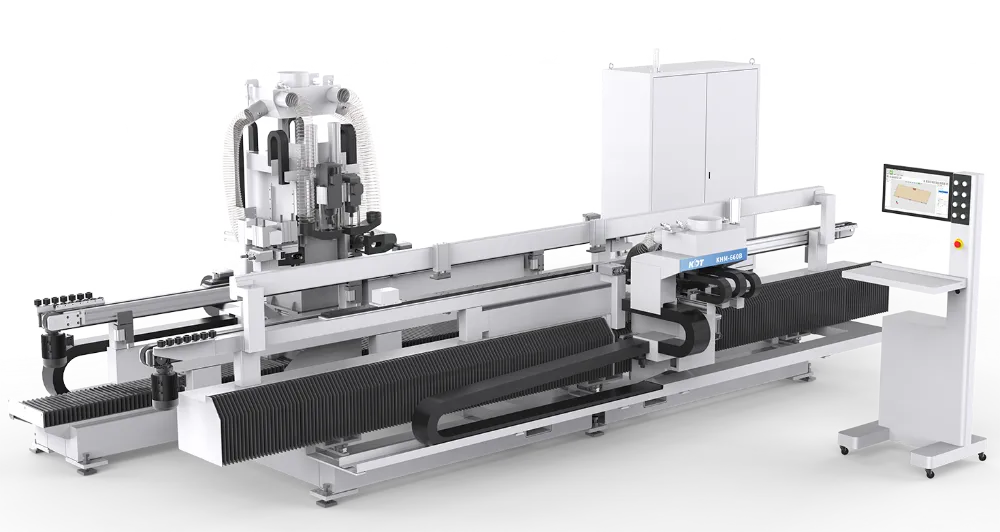

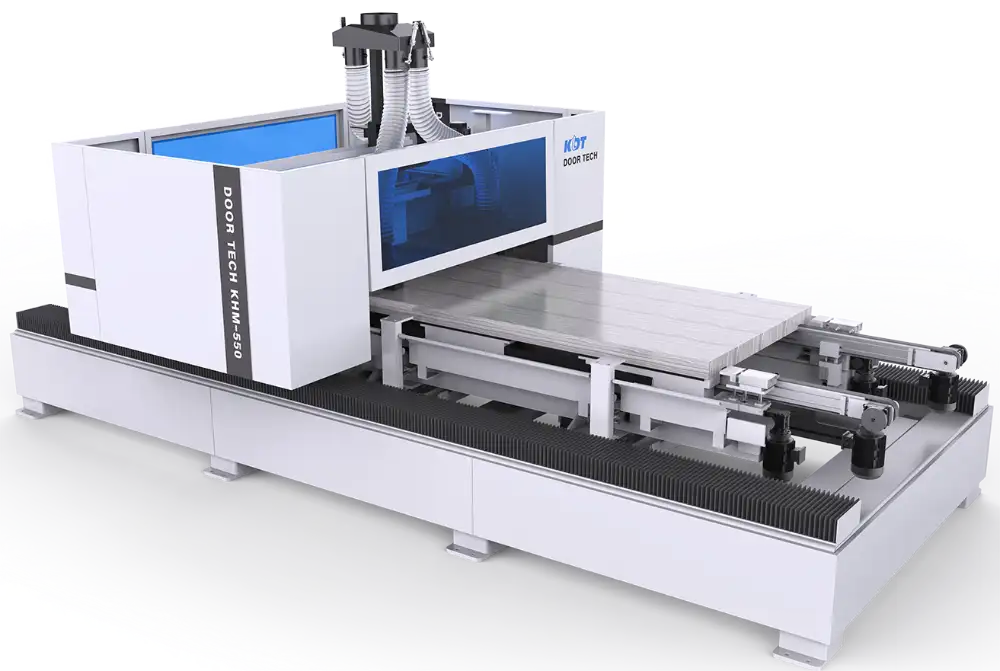

At KDT Ibérica, we understand the importance of this transformation and we make available special machinery for the machining of doors.

This process not only optimises production times, but also opens up a wide range of possibilities in terms of shape, finish and design, adapting to the specific needs of each project.

What is door machining and why is it important?

Door machining consists of the application of various mechanical operations on the surface and structure of the door to adapt it to specific requirements. This process goes beyond simple squaring, ranging from the machining of the door surface to the machining of the door structure. of hinges and locks to the production of sliding door grooves and the machining of frames for some models.

The importance of machining lies in its ability to transform a basic material into a finished product with superior functional and aesthetic characteristics.

Thanks to the machinery for door machining, precise modifications are possible and guaranteed:

- Perfect fit of fittings

- Increased durability of installations

- Improved door functionality

- Optimisation of production times

The machining centres for doors have revolutionised the way in which these construction elements are conceived, allowing each project to have solutions that are truly adapted to its particular needs.

Advantages of industrial machining over traditional methods

The implementation of door machining centres in industry has resulted in a vast improvement over traditional methods. The main advantages include:

- Greater accuracy and consistency

Numerical control technology makes it possible to achieve an accuracy that would be impossible by manual methods. This accuracy is important to ensure that elements such as locks and hinges function correctly throughout the life of the door. - Reduction of production times

A machining centre can complete all necessary operations in a fraction of the time that manual work would require. This efficiency makes it possible to meet the demands of tight project deadlines. - Capacity for complex designs

The machining of designer doors benefits from CNC technology, as it allows patterns and shapes to be made that would be extremely difficult or impossible to achieve manually.. - Resource optimisation

Computerised systems calculate the most efficient way to perform each operation, minimising material and energy waste. - Production flexibility

The same machining machine can be quickly adapted to work with different door models, facilitating customisation without slowing down production.

CNC technology: the revolution in door machining

Computer Numerical Control (CNC) technology has marked a turning point in door machining. This technology makes it possible to accurately program every operation to be carried out by the machining machine, guaranteeing consistent and high quality results.

Numerical control for door machining works by means of computer systems that translate digital designs into precise instructions for the machines in charge of cutting, drilling and other types of machining. This automation of the process provides multiple advantages such as:

- Repeatability of complex patterns and designs

- Significant reduction in human error

- Material optimisation and waste reduction

- Ability to perform complex operations in a single configuration

The work centres for doors equipped with CNC technology allow any design to be accurately transferred to the material, opening up a world of possibilities for architects, designers and builders.

The future of machining in the door industry

The door machining sector continues to evolve, driven by technological advances and increasingly specific market demands. The combination of advanced CNC technology with the expertise of professionals is raising the standard of quality and possibilities in the industry.

Door machining centres are becoming more versatile, integrating different operations on the same machine and thus reducing production times. Technology is also making it possible to more efficient loading and unloading of materials when integrated into flexible production lines, optimising the entire production process.

For construction and design professionals, keeping up to date with the possibilities offered by door machining is essential to realise its full potential in future projects. The precision, versatility and customisation capabilities of this technology will continue to be the key to the future. differentiating factors in an increasingly demanding market.

At KDT Ibérica we have a catalogue of machinery for door machining that adapts to the needs of each customer, from small workshops to large industries. Our selection allows us to carry out any type of work with maximum efficiency. guarantee of quality and durability.